Instantly find the webinars and videos you are looking for to learn about new versions, features, add-ons, applications and more

Summary

Aug 31st | Sept 14 | Sept 28th | Oct 19th

Join the DCS expert team to learn about the new updates in 3DCS Version 8.0 - Now Available Through DCS FileShare

April 2023

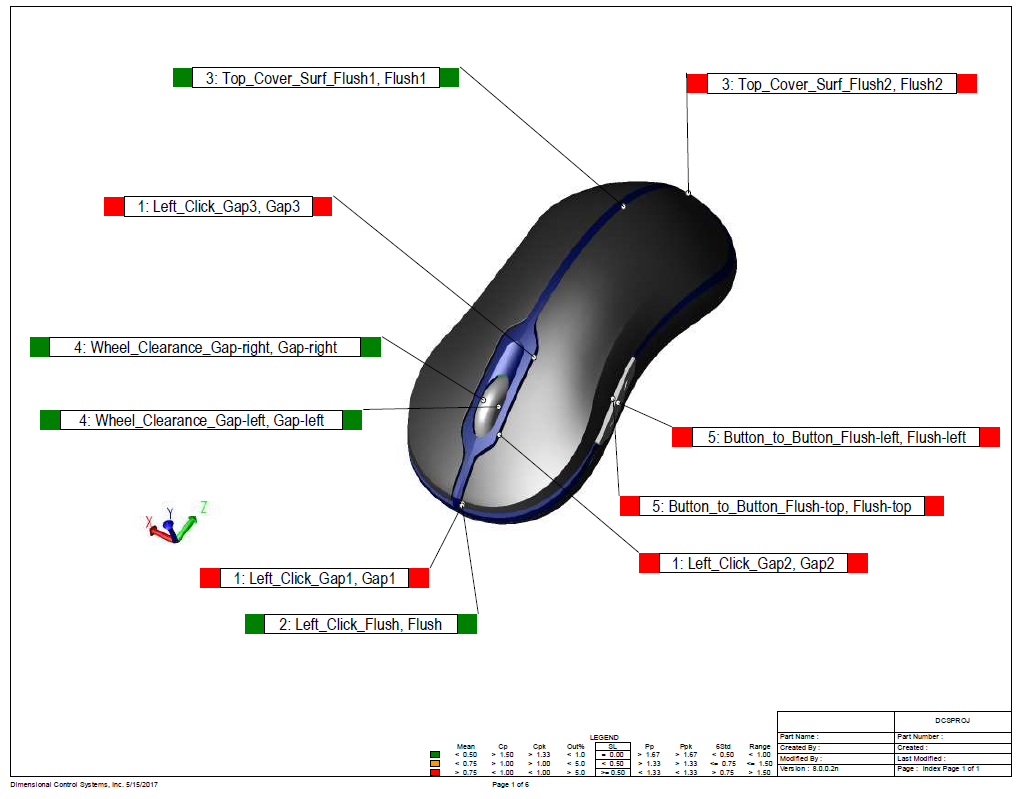

See 3DCS connect with Silma and Metrolog

October 2022

Agenda:

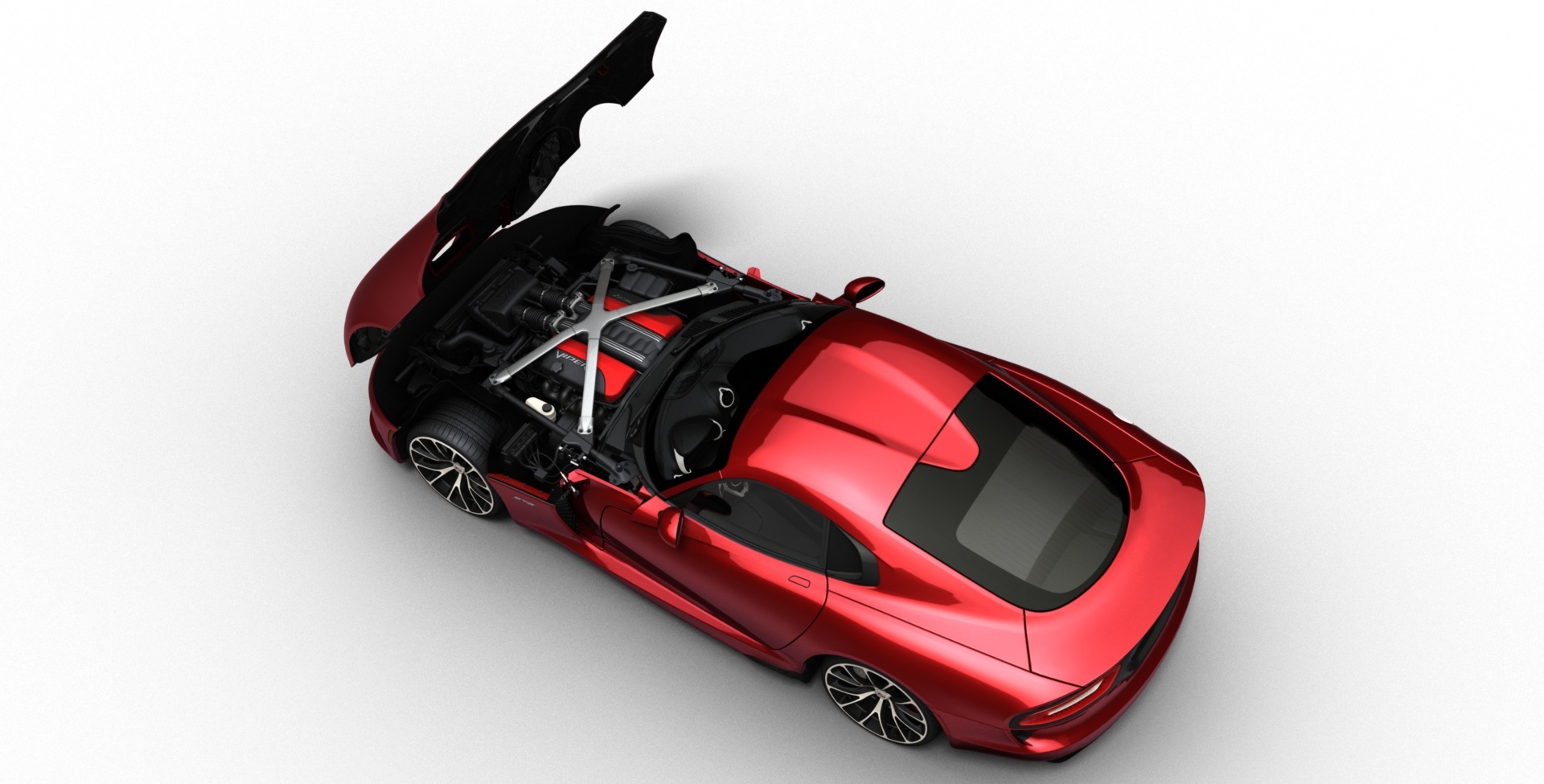

Join Dassault Systemes, SME, and DCS to see firsthand how visualization with Ray-Tracing and VR provide real-world insights into product craftsmanship, and most importantly, the tools to control and improve craftsmanship across the product line.

February 2023

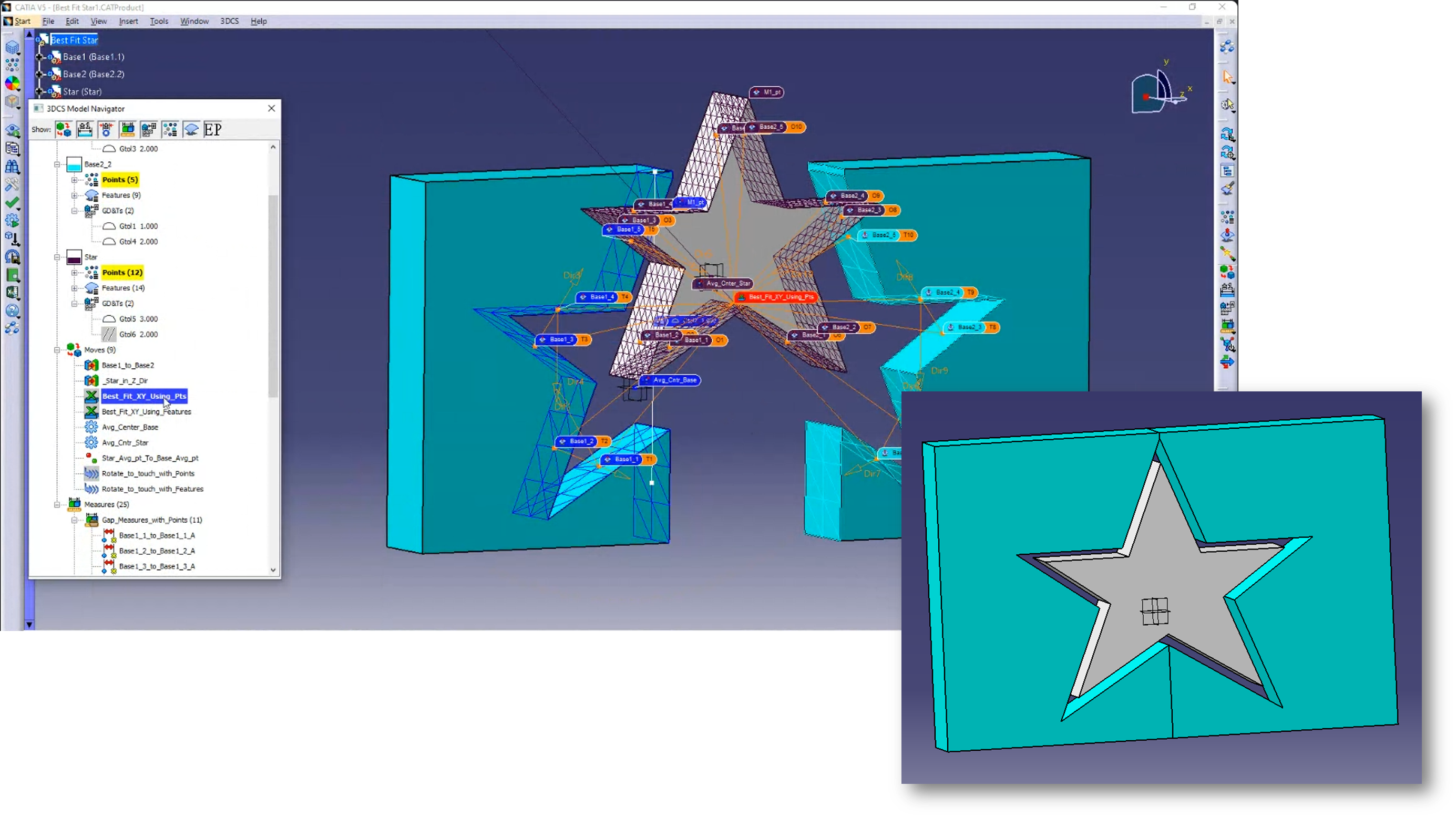

Webinar showcasing Best-Fit Move, as well as Optical Analysis for beam direction, which can be applied to sensors, lights, lasers, and other projections.

In addition, you'll see modeling techniques

In addition, you'll learn:

January 2023

Take a look at the Agenda:

- Learn Tips, Benefits, Methods, and Tools

August 2022

What You'll Learn:

September 2022

What You'll Learn from the Gear Variation Model:

May & June 2022

Part 1

Part 2

April 2022

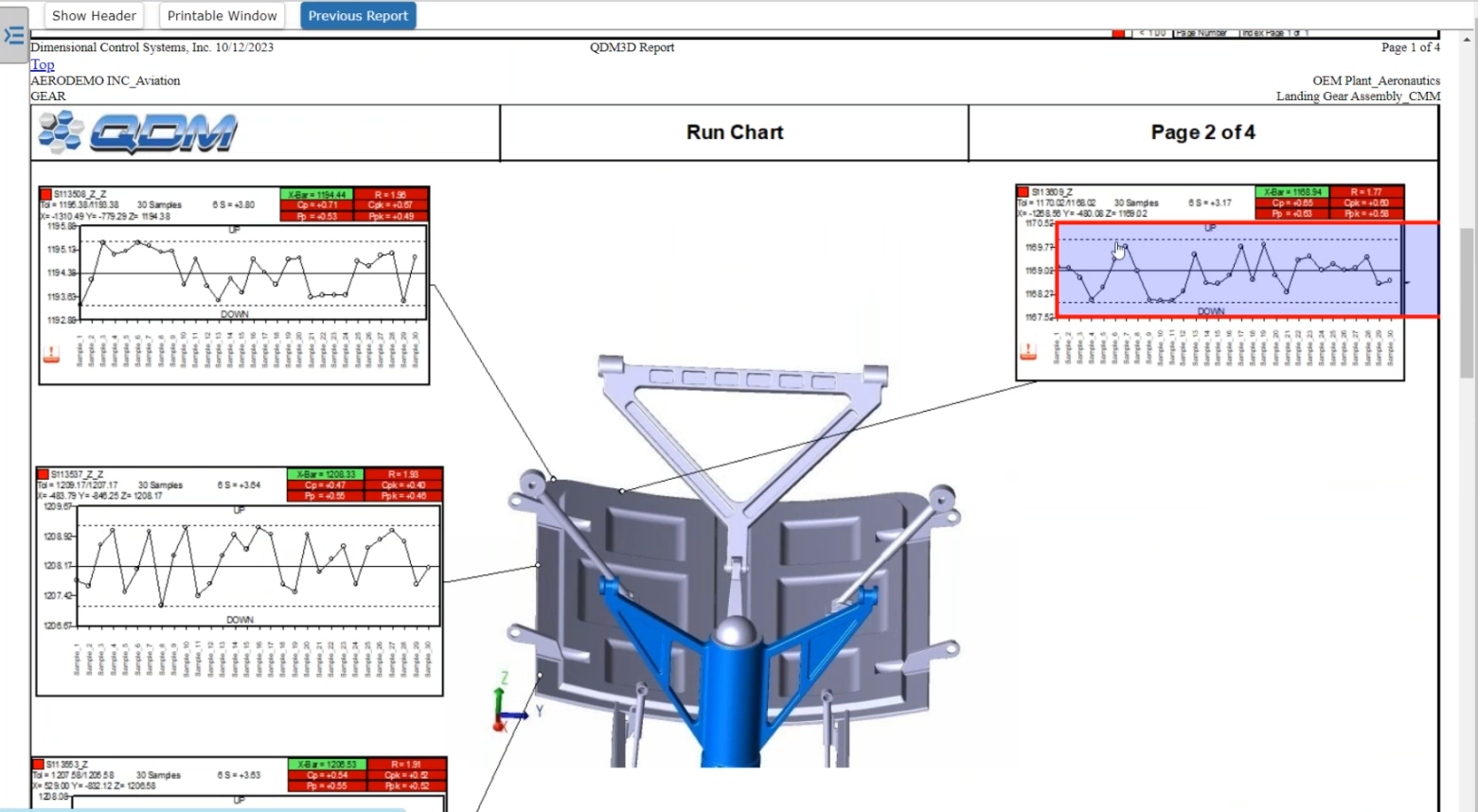

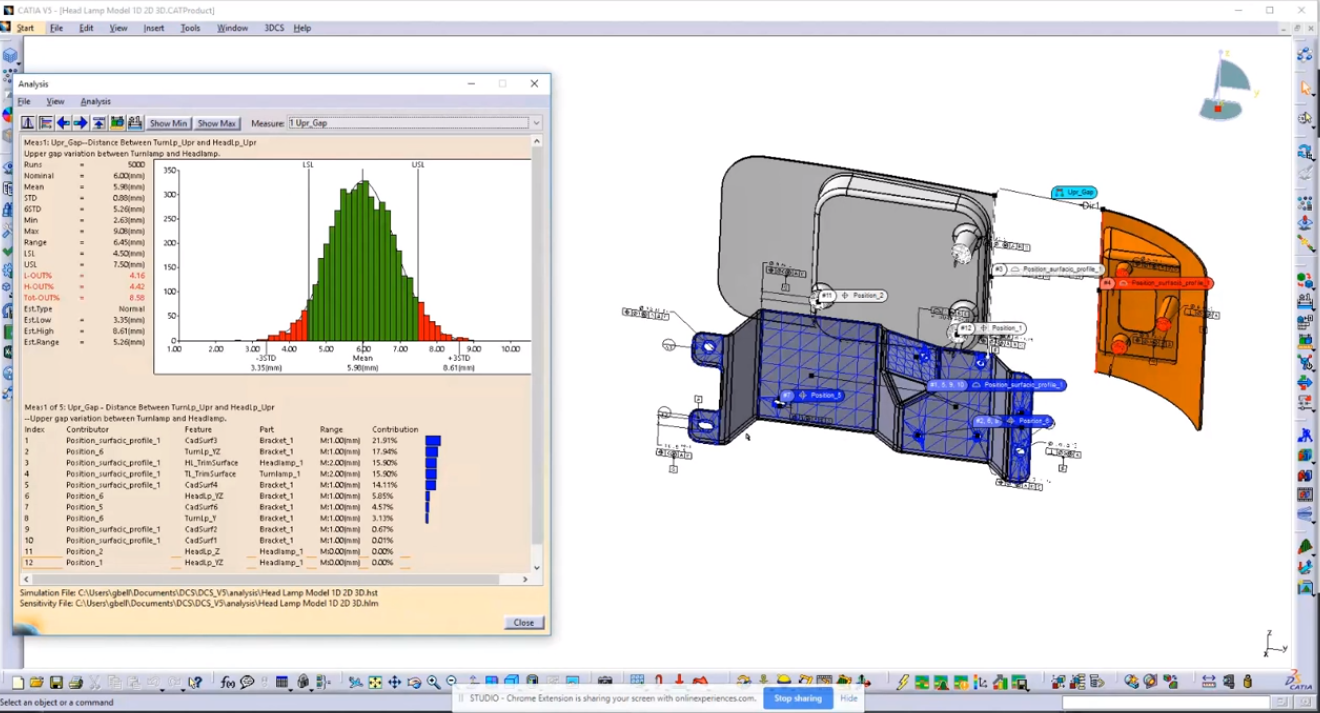

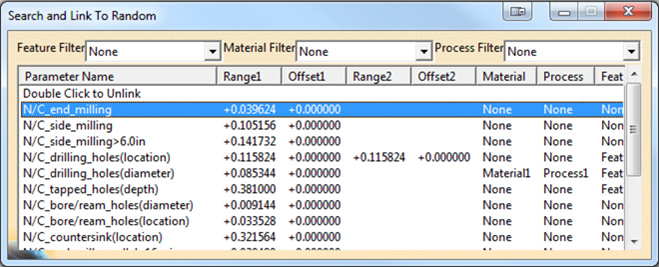

In this webinar, learn how to automate the use of measurement data in 3DCS Variation Analyst to run tests, simulations, analyses, and root-cause analyses on your manufacturing quality. Utilize your CAD points with your CMM to easily correlate the data and unlock the power of 3DCS software for your as-built products.

March 2022

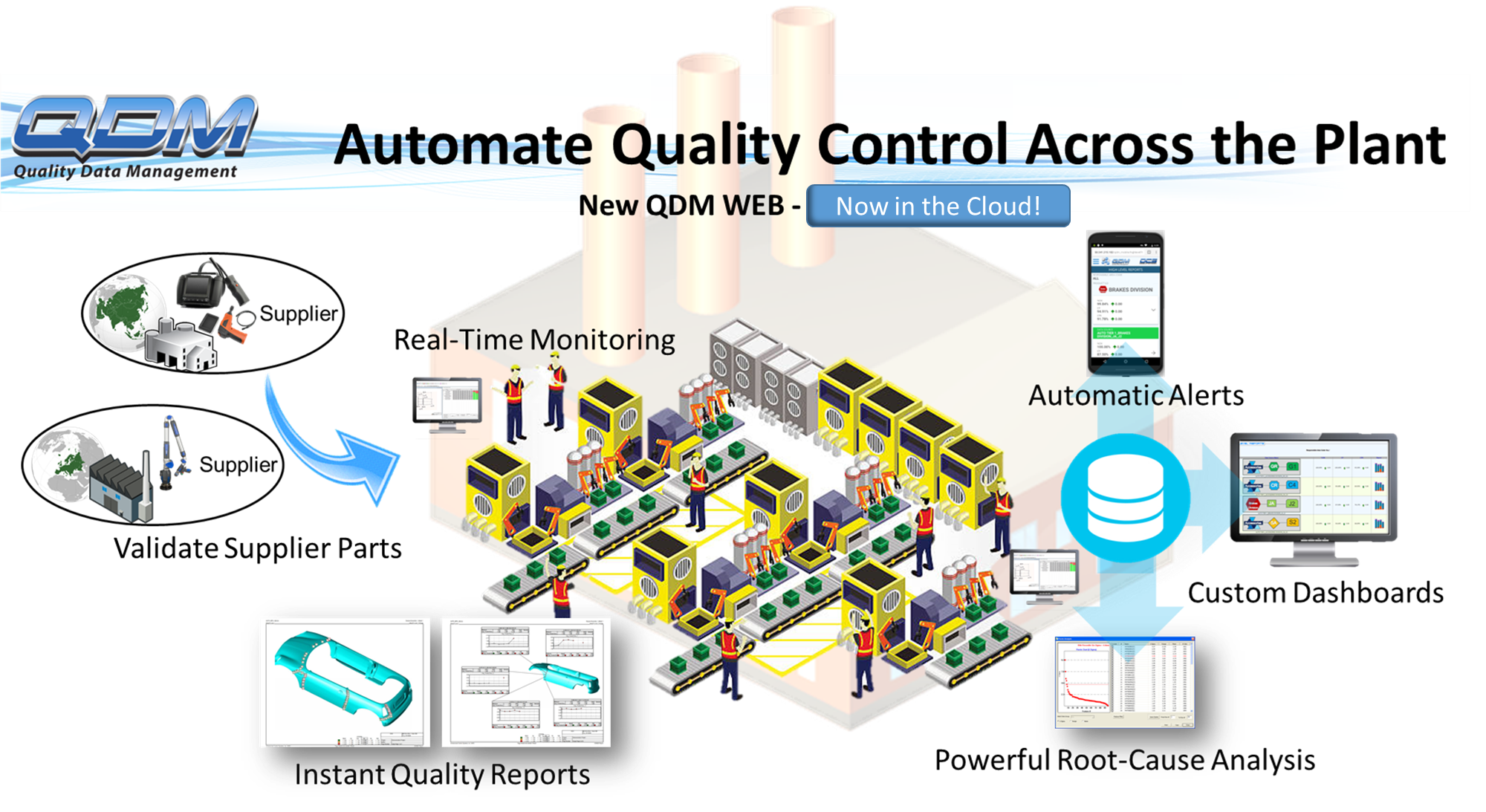

In the webinar, you'll see how the Digital Twin can be used along the product lifecycle to drive quality throughout the process. By leveraging Quality 4.0 concepts, the Digital Twin Exchange moves the Digital Twin from system to system, utilizing the CAD information to standardize information and correlate design and manufacturing. The process starts in early digital design, and then pushes measurement plans and instructions, delivers inspection, creates SPC quality control, and delivers powerful root cause analysis.

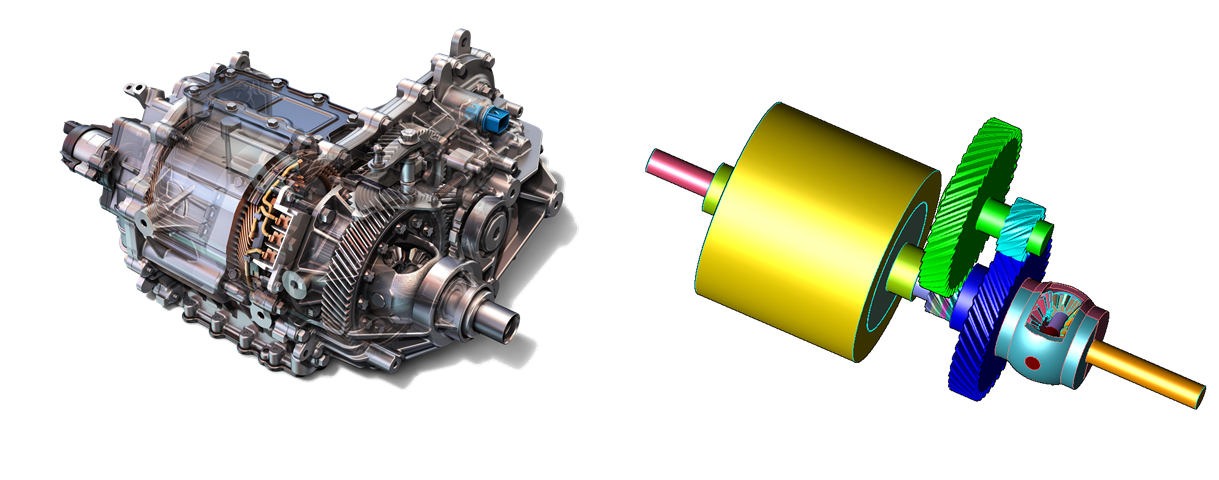

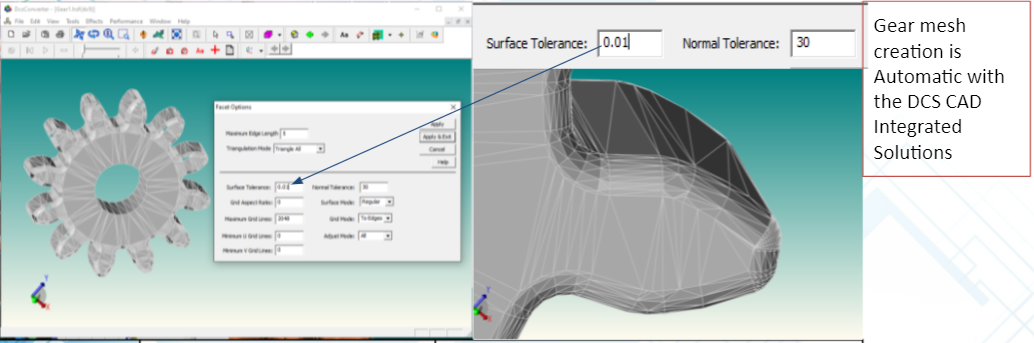

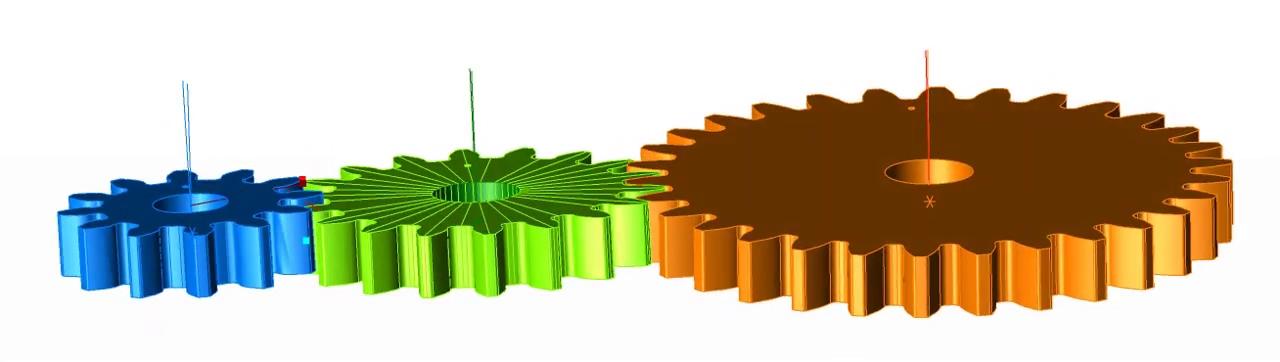

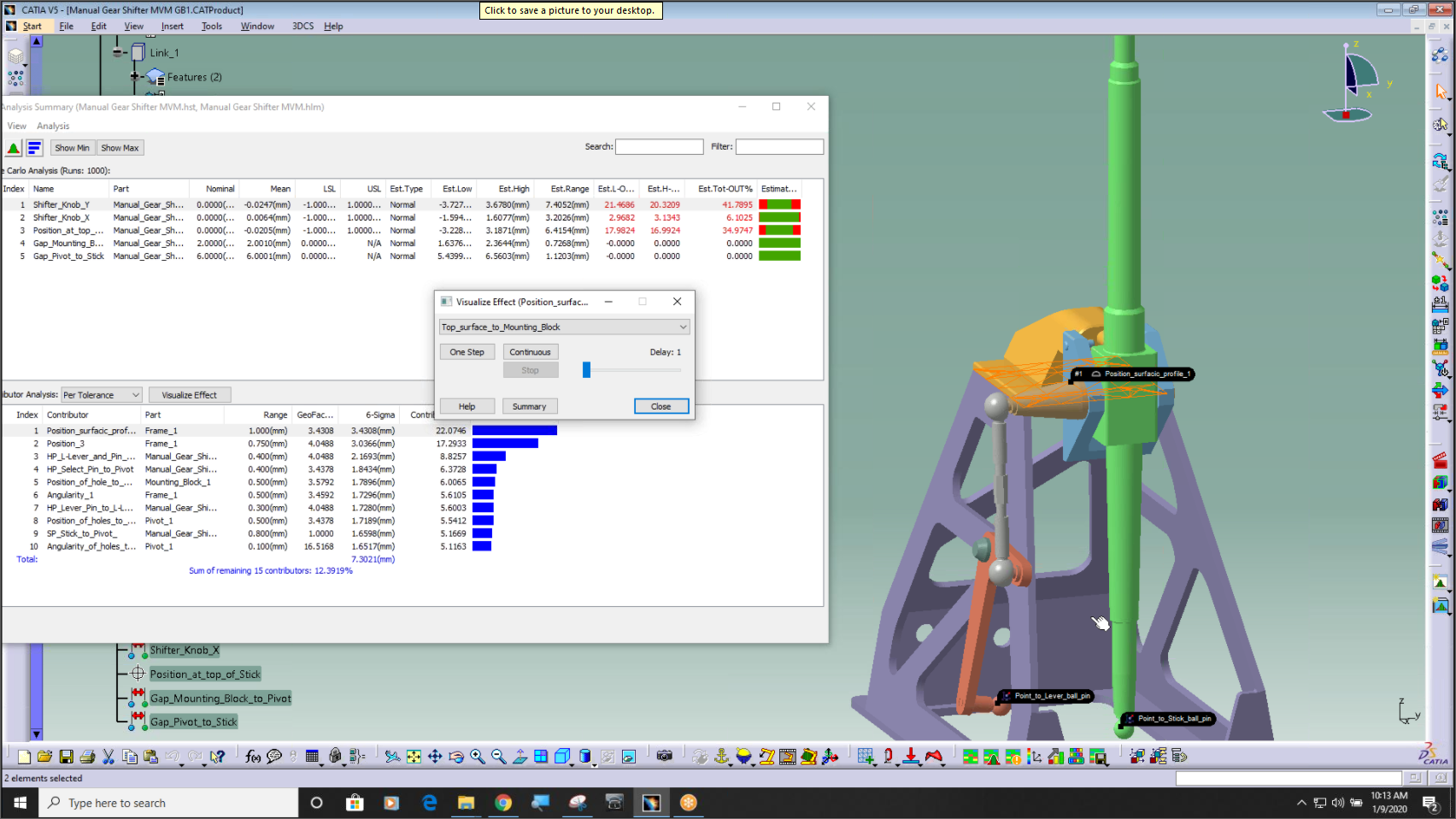

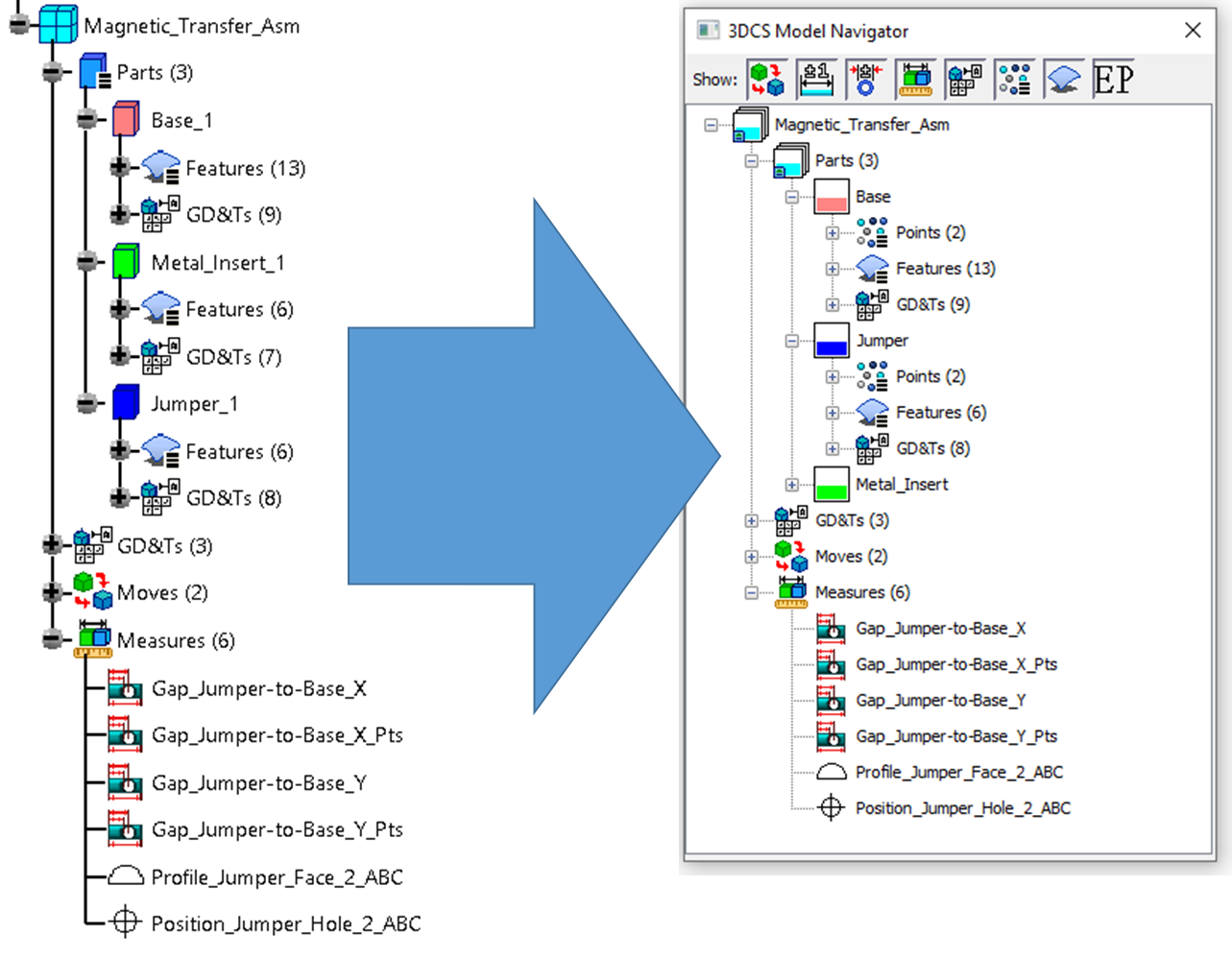

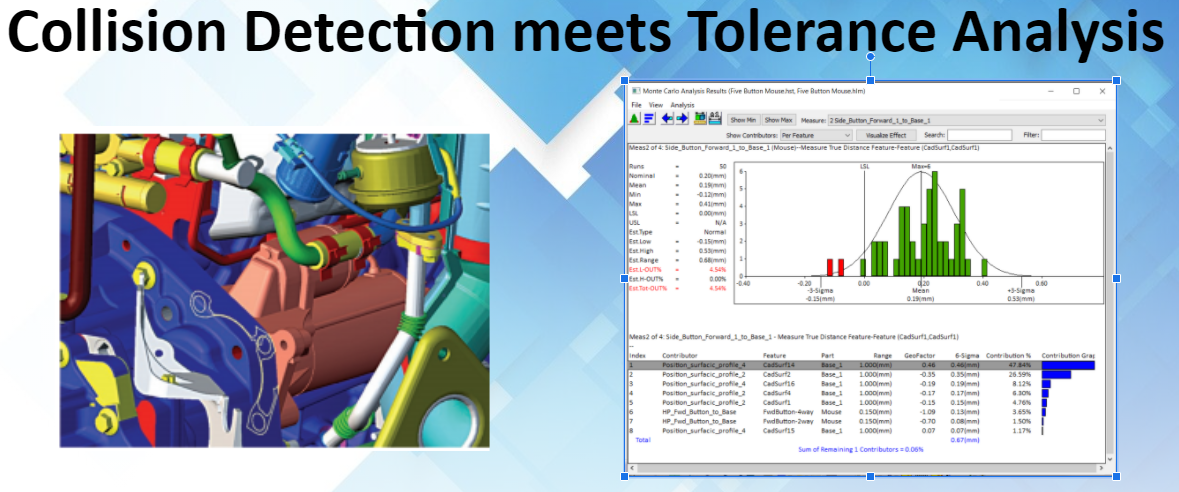

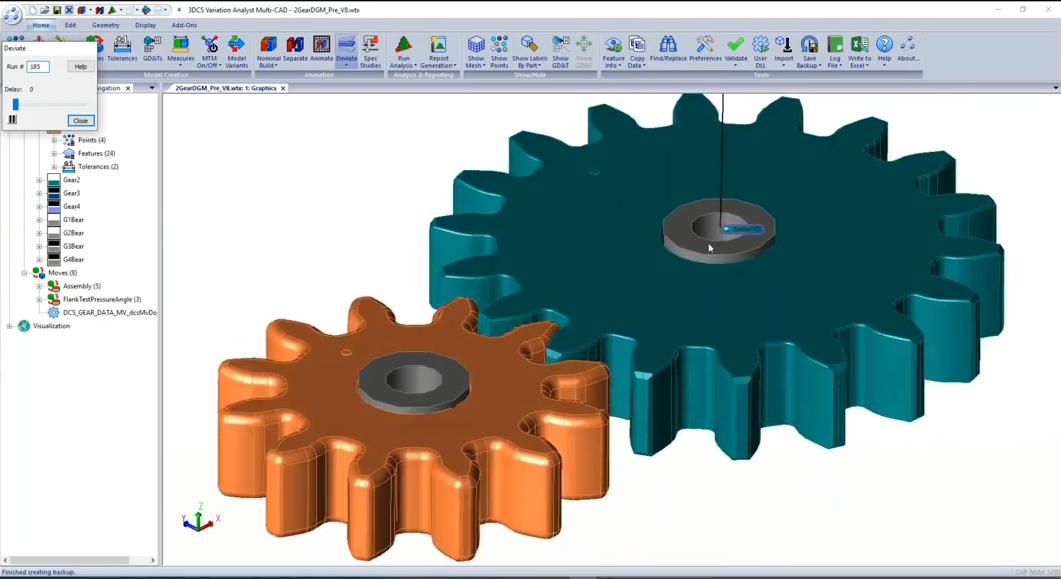

The first part of the 7.8 Webinar Series will showcase two new features; the Gear Module and Collision Detection. This will include an overview, with a link to watch a more in-depth video on how to use the new tools.

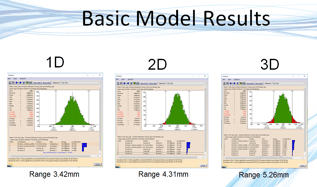

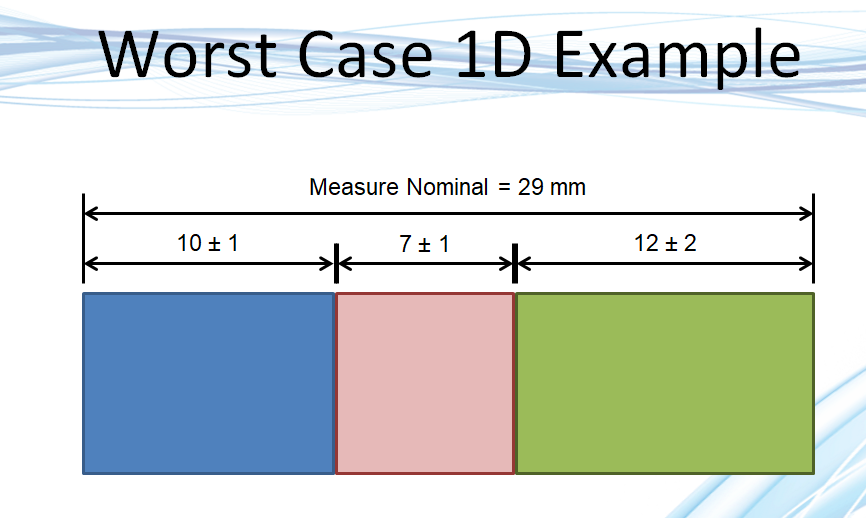

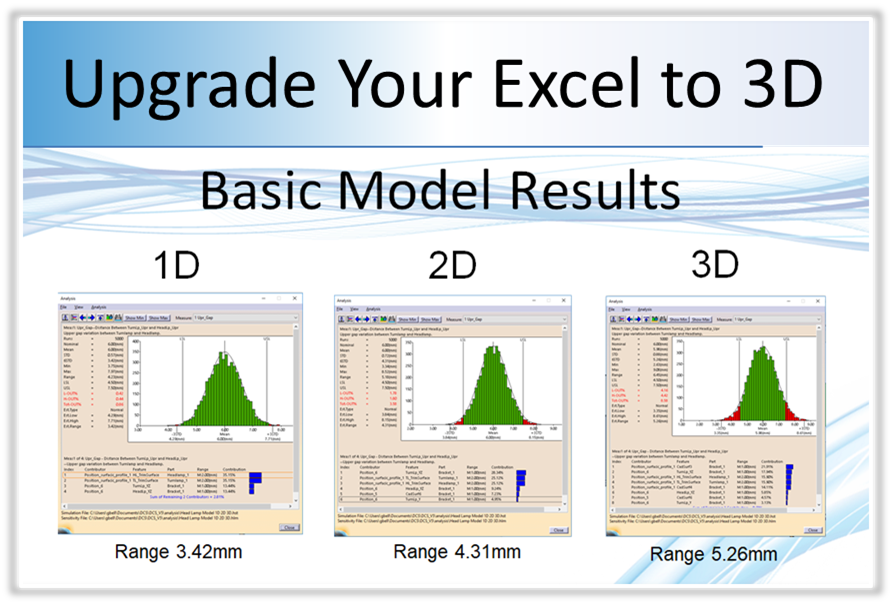

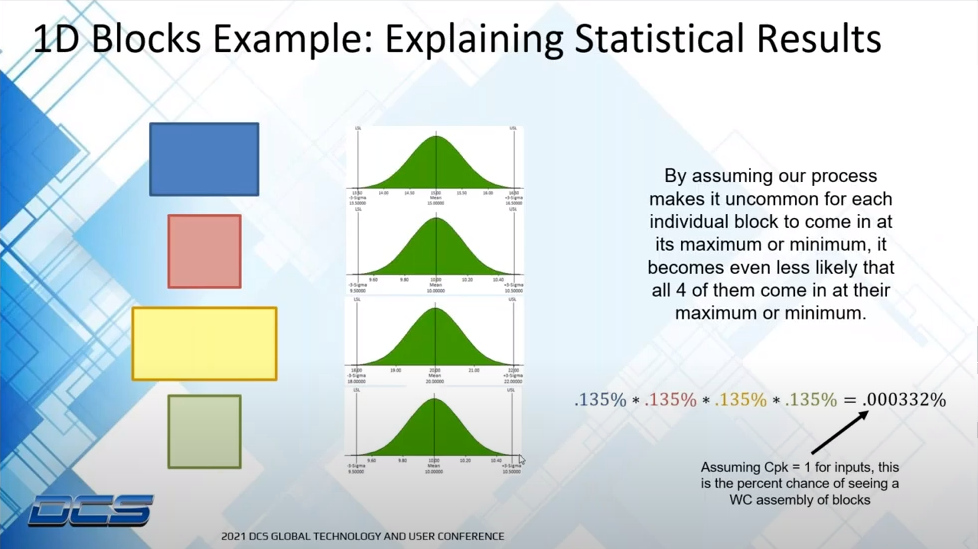

Why Excel is Failing Your Tolerance Stack-Ups

Learn how 1D and 2D stacks in Excel are missing important influences and wasting time with recalculations.

Learn how to calculate Worst Case in 3DCS tolerance analysis software and why Worst Case analysis may be contributing to high production costs unnecessarily.

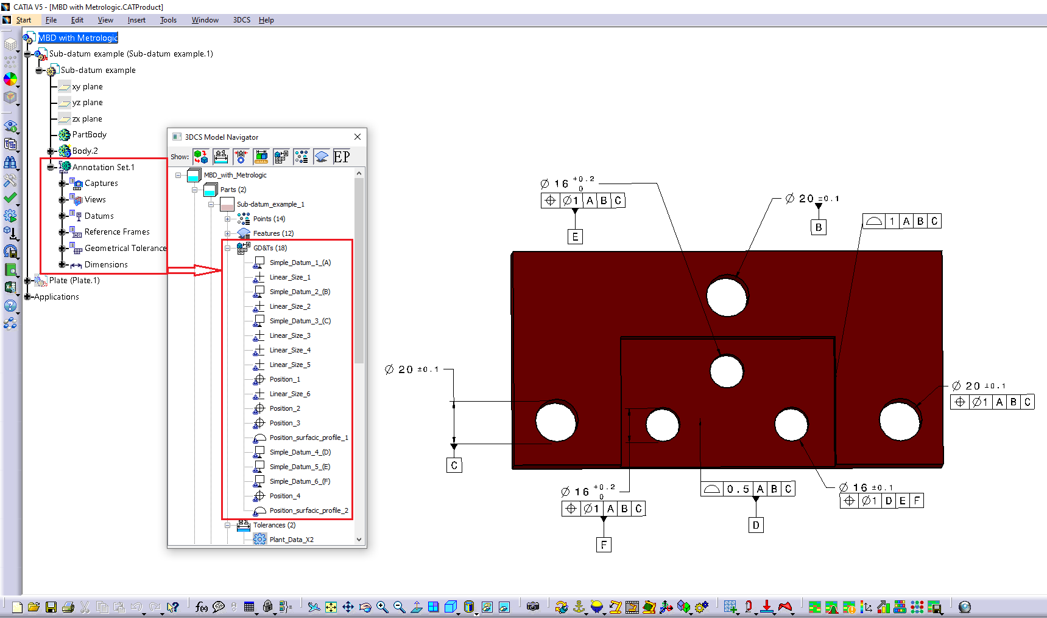

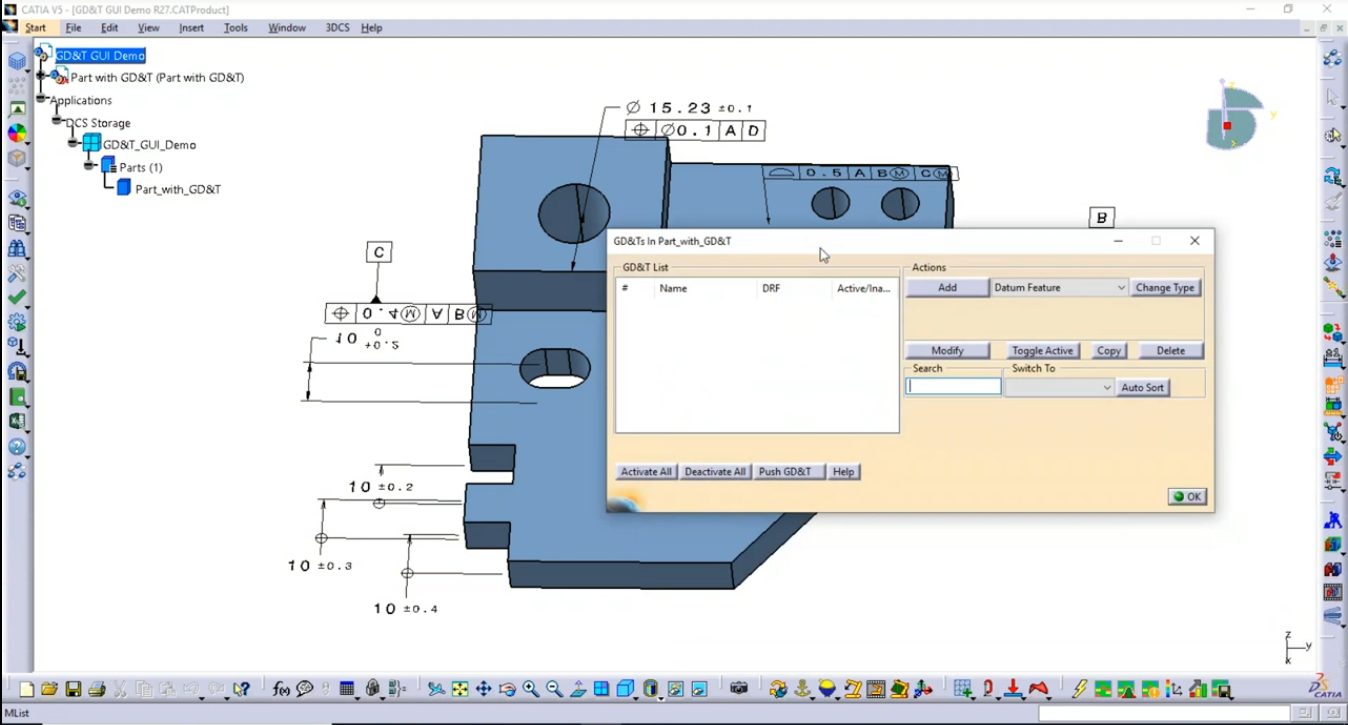

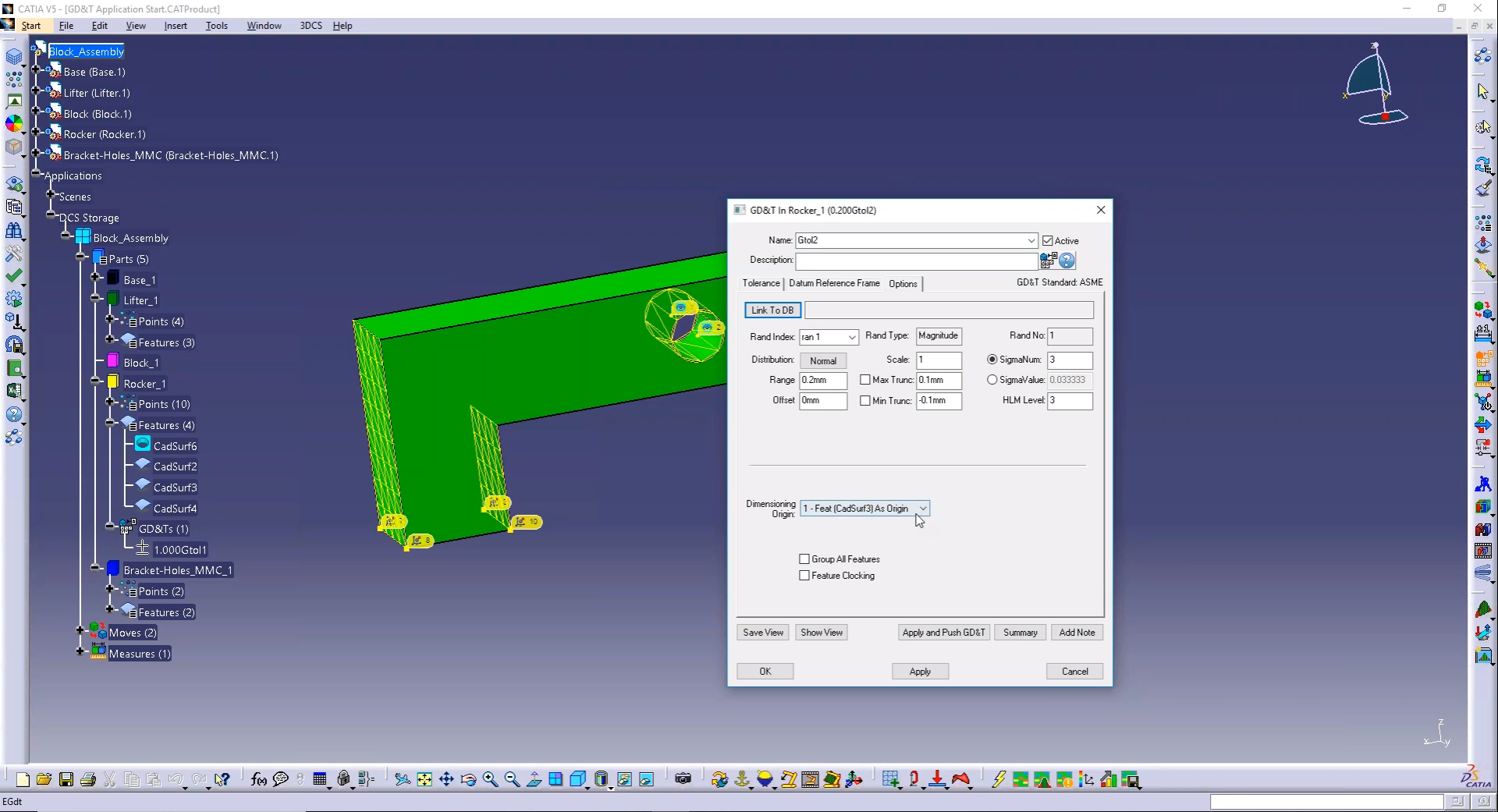

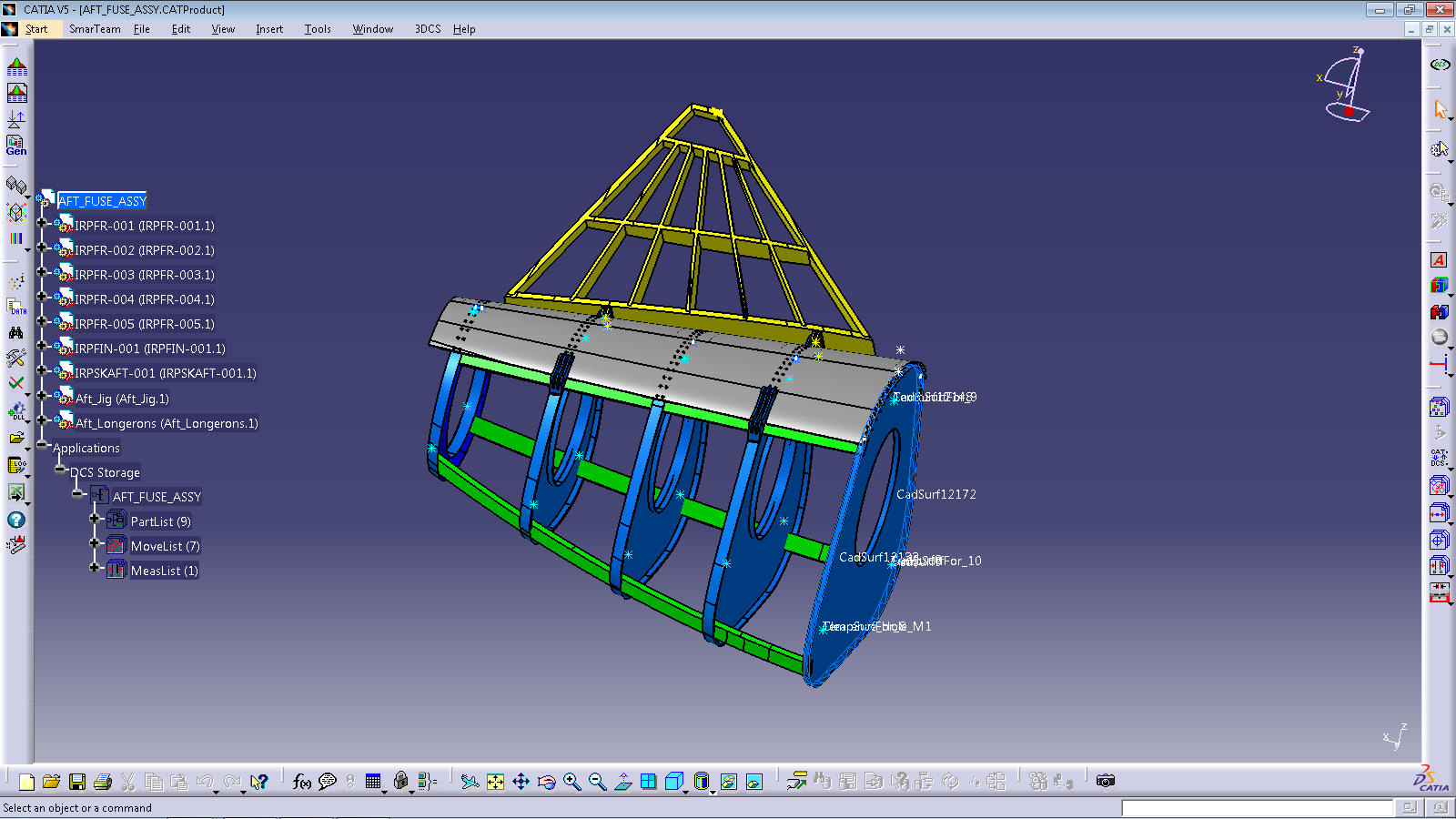

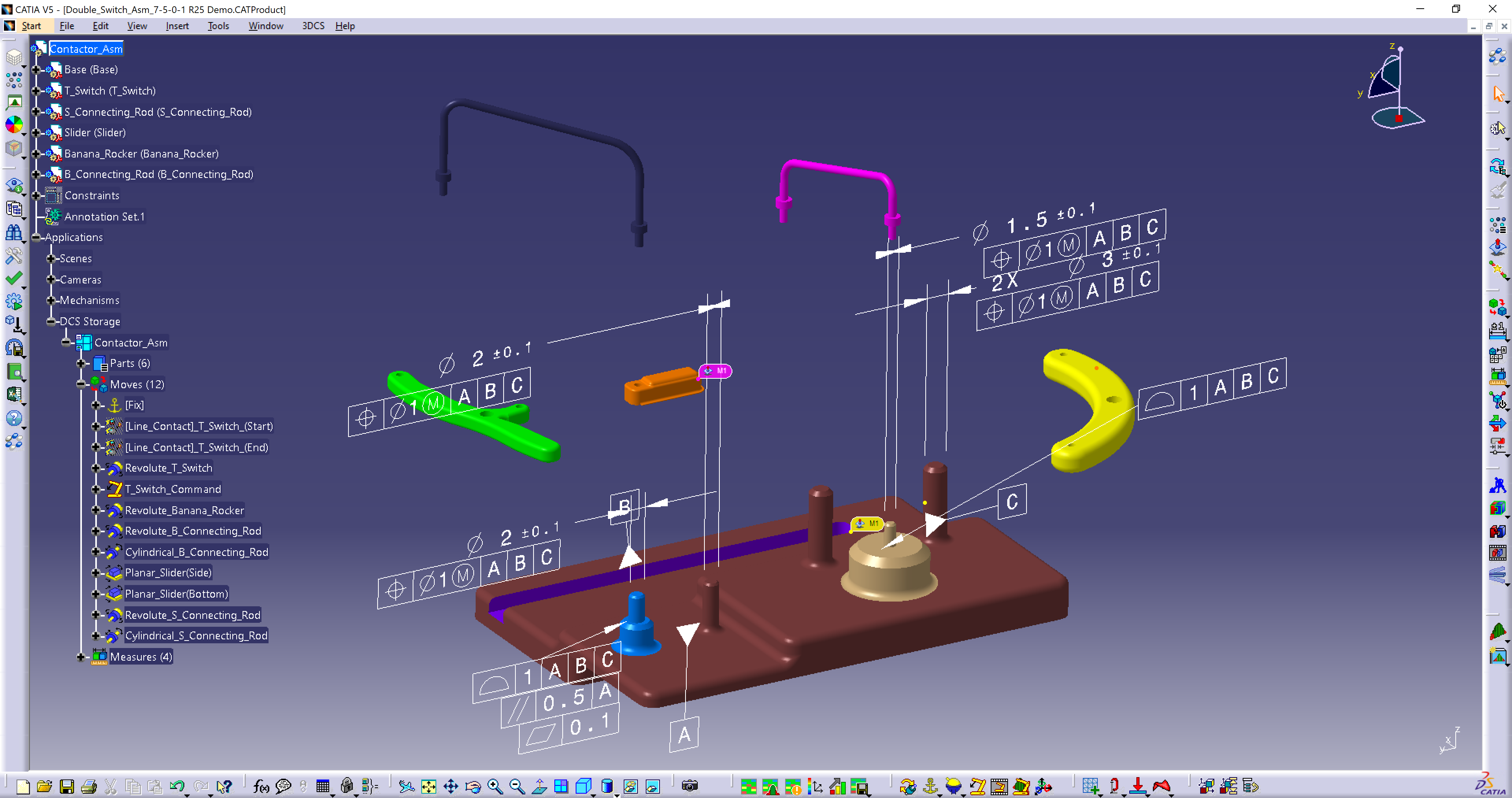

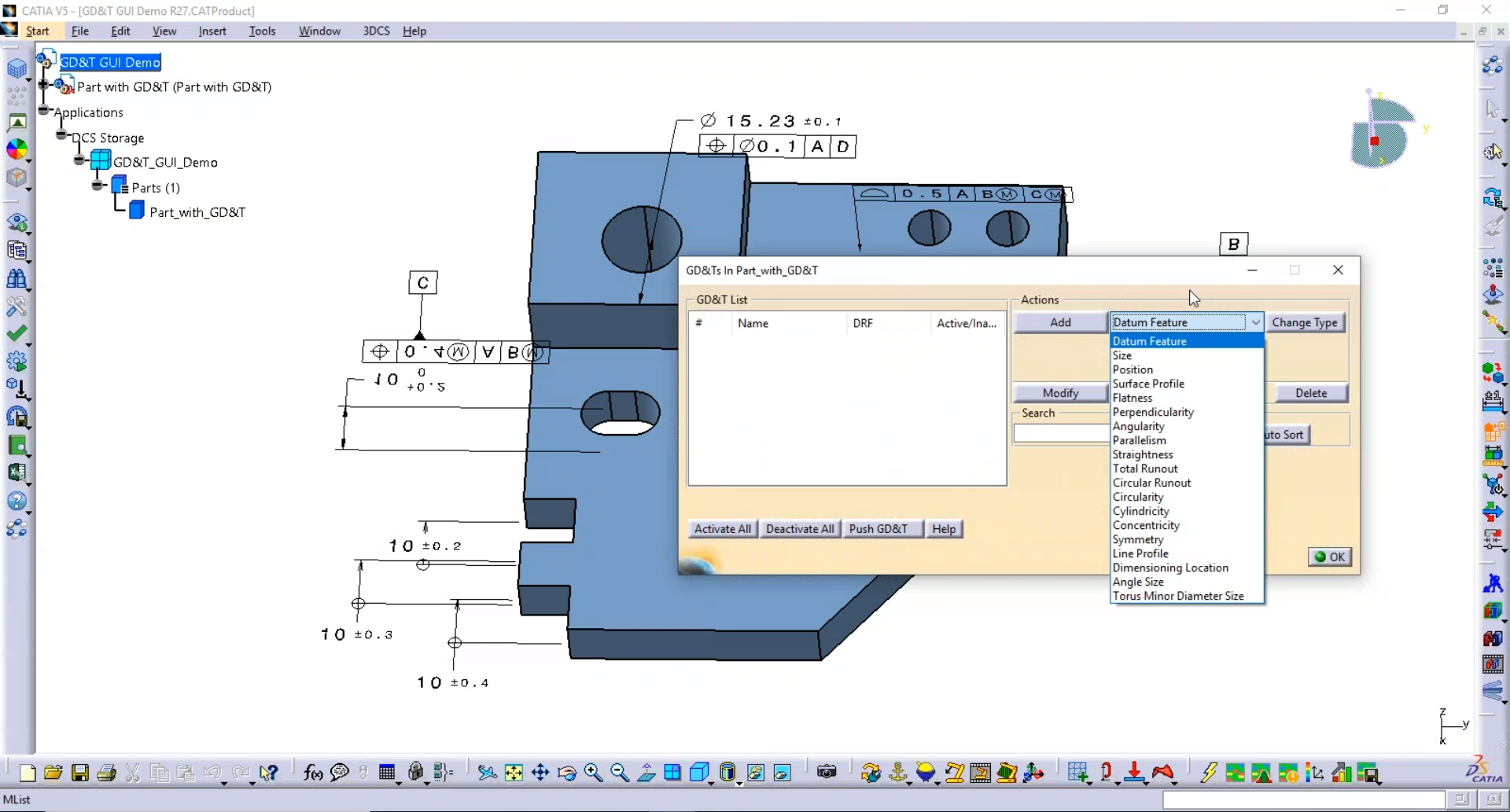

3DCS fully integrated into CATIA V5

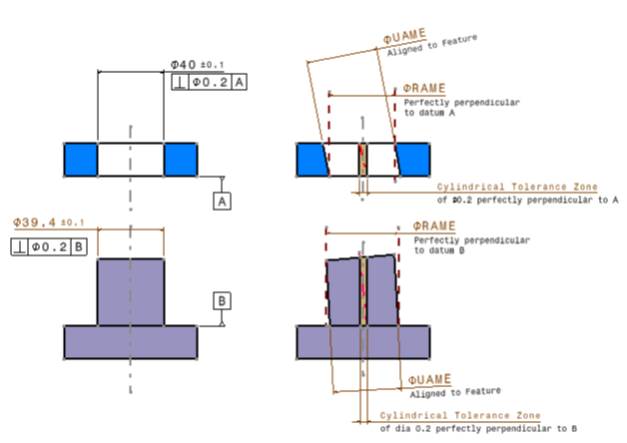

Guest presenter Gary Carne, Dassault Systemes, and Gary Bell, DCS, demonstrate the use of GD&T in CATIA and how to use it to support Model Based Design

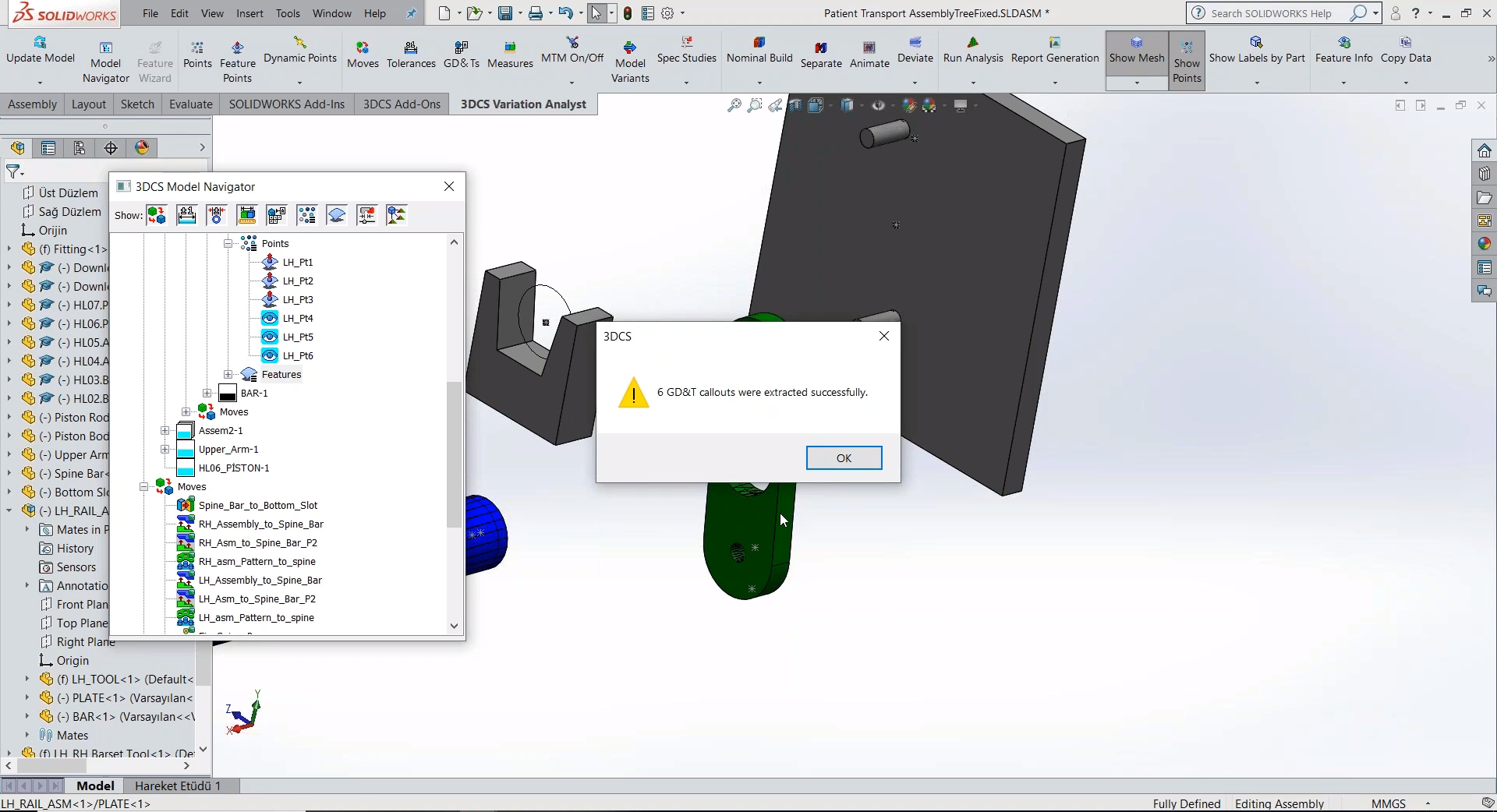

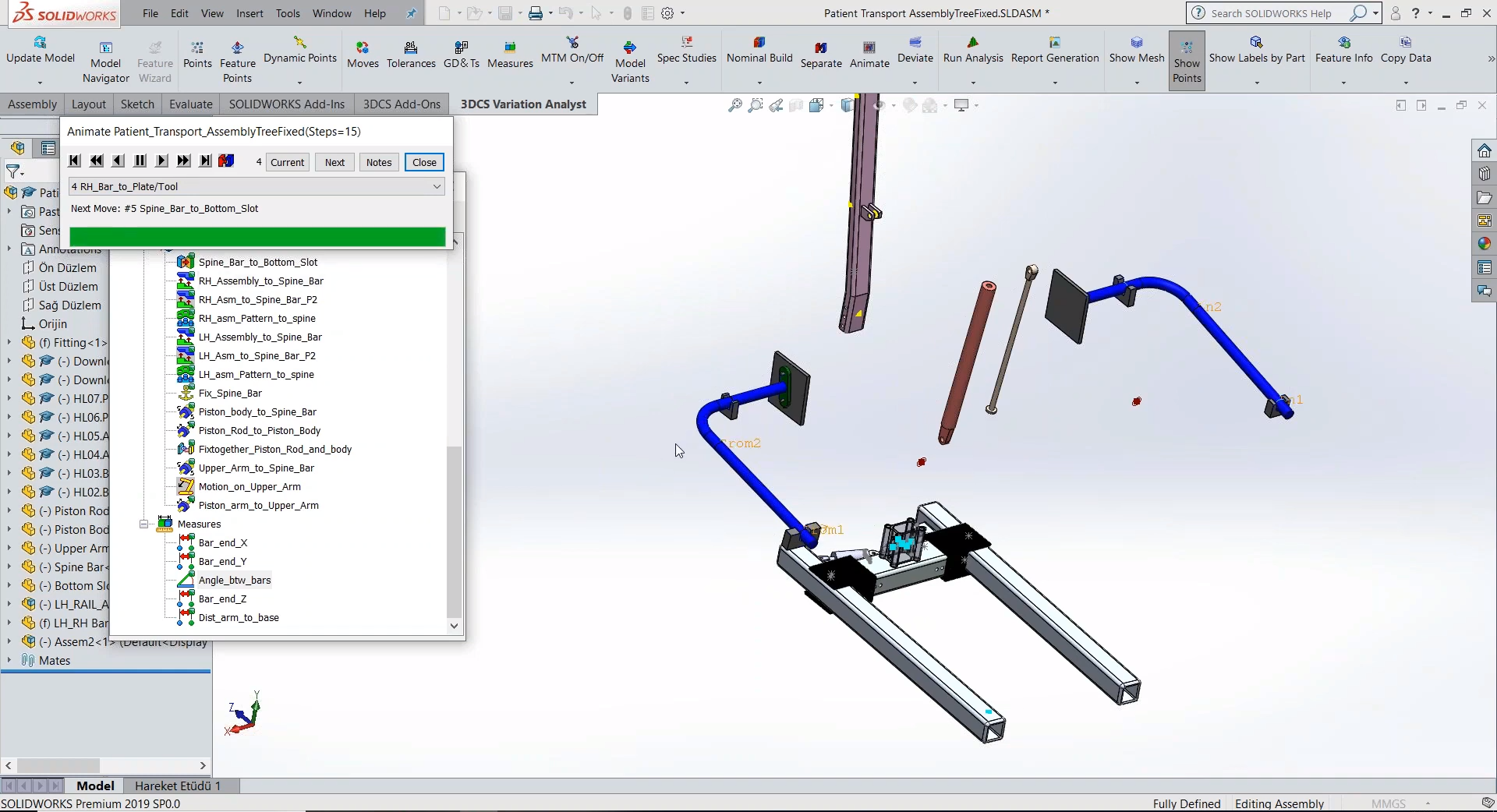

3DCS fully integrated into SOLIDWORKS

3DCS fully integrated into SOLIDWORKS puts powerful tolerance analysis tools right at your fingertips, accessible from inside your CAD platform.

Learn how to create embedded GD&T in CATIA , NX and CREO

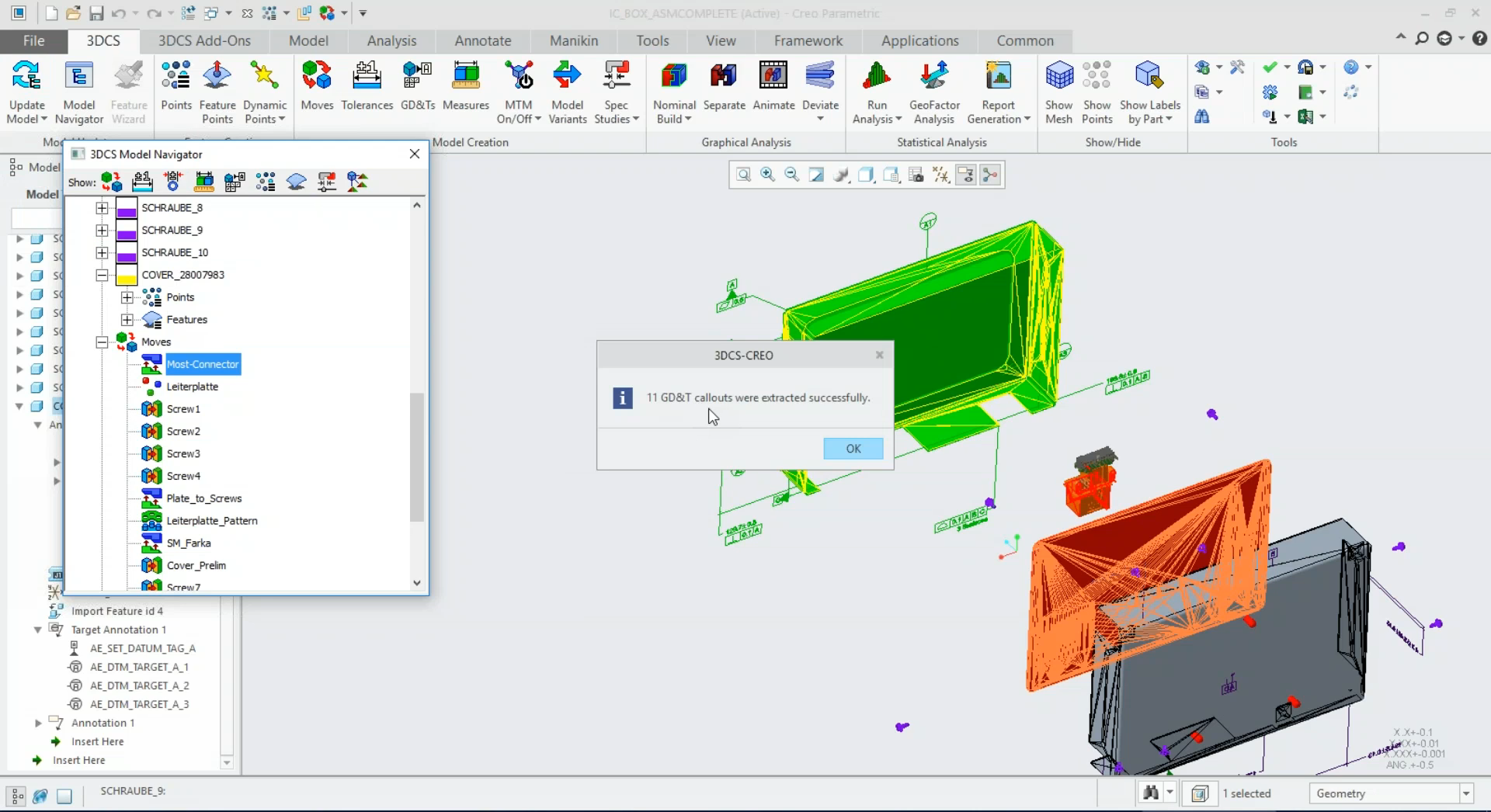

3DCS fully integrated into PTC CREO

Showcasing 3DCS for Creo fully integrated into Creo Parametric, this is an excellent webinar for new and experienced 3DCS users looking to use Creo and 3DCS together.

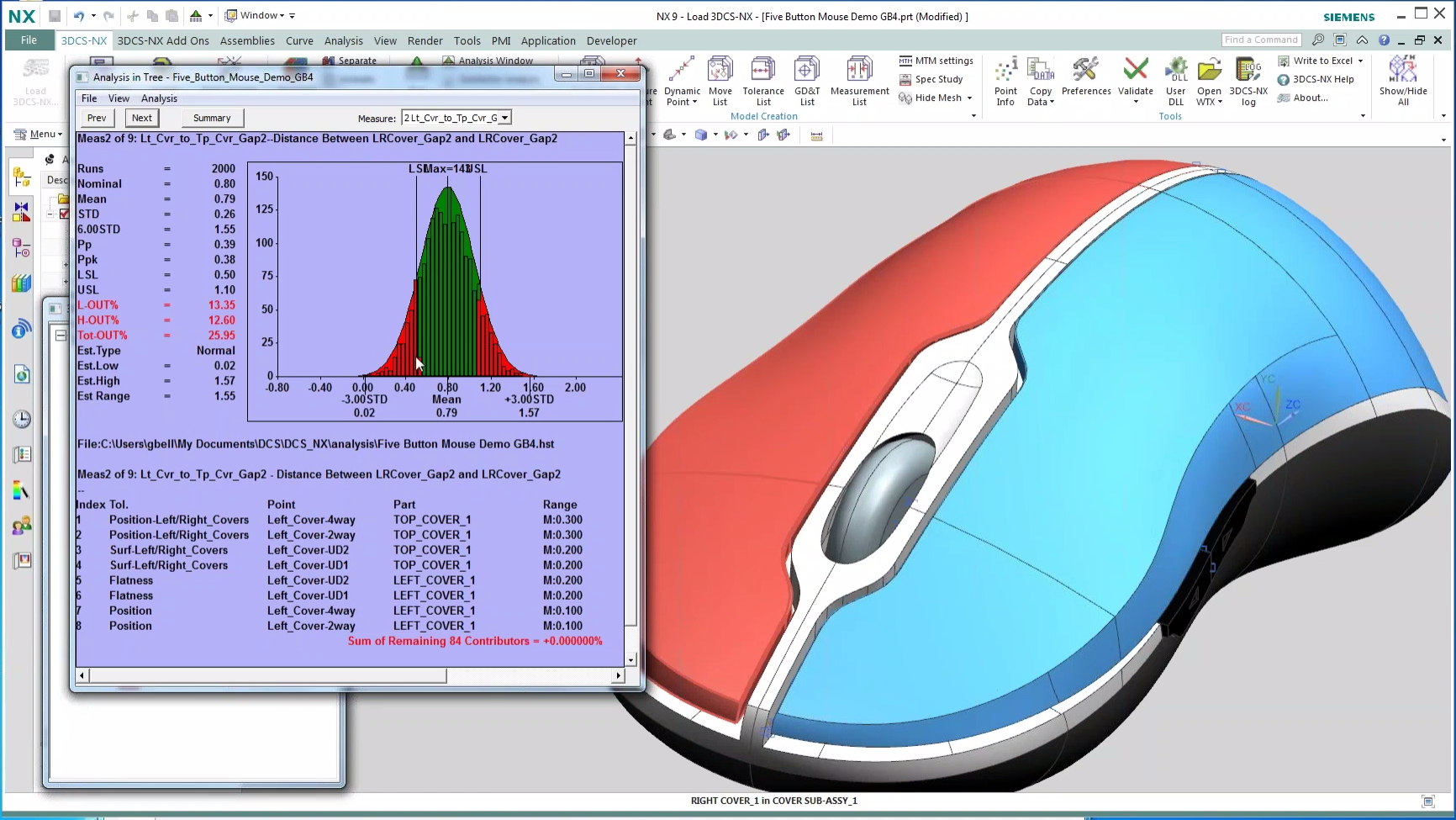

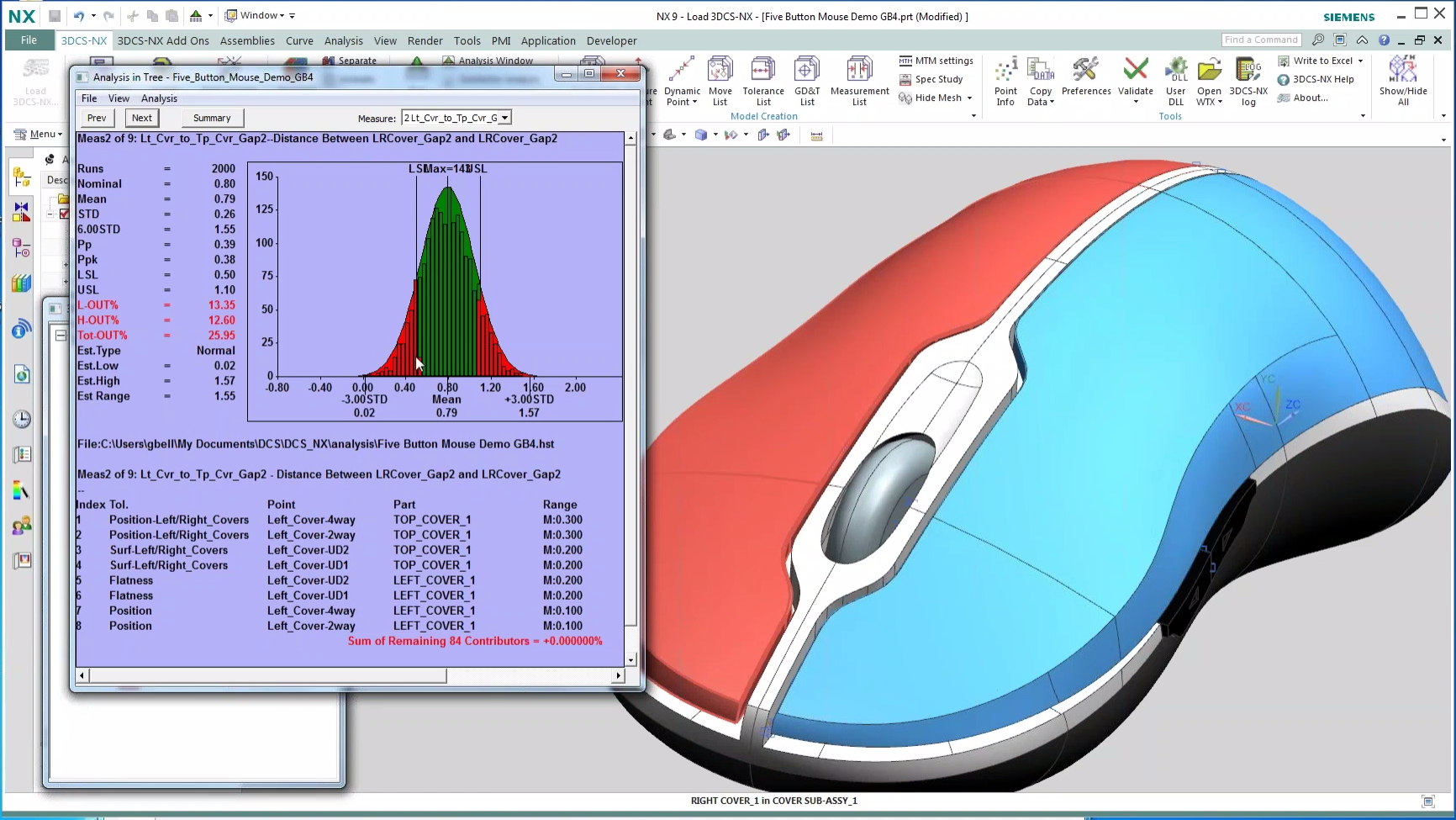

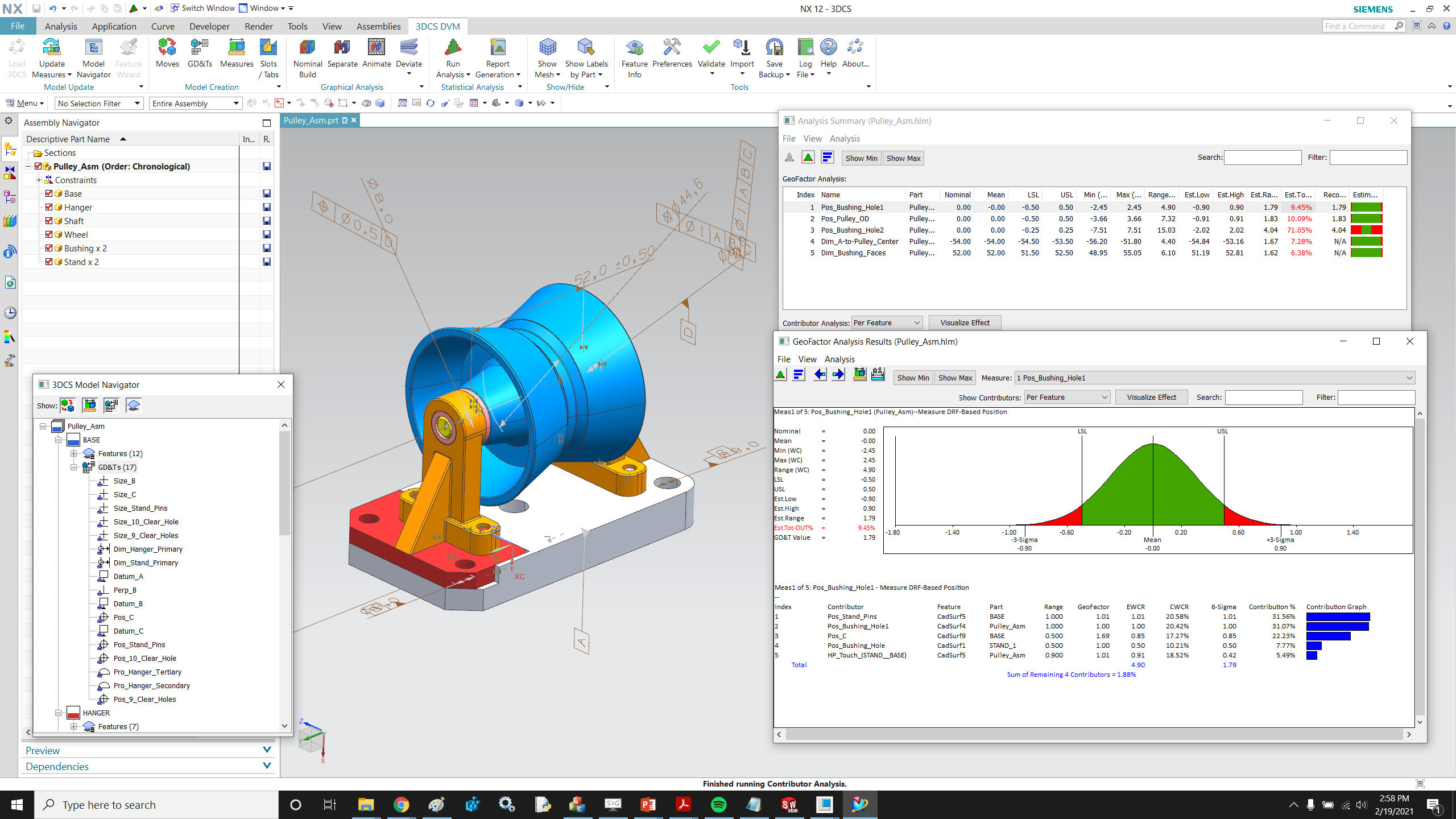

3DCS fully integrated into Siemens NX CAD

3DCS for NX includes all of the functionality of 3DCS's other versions [Multi-CAD, CATIA V5], as well as giving access to Add-on modules to for additional functionality [Advanced Analyzer Optimizer, FEA Compliant Modeler, Mechanical Modeler, Visualization Export, Geofactor], but also leverages the tools and add-ons found in the NX CAD system.

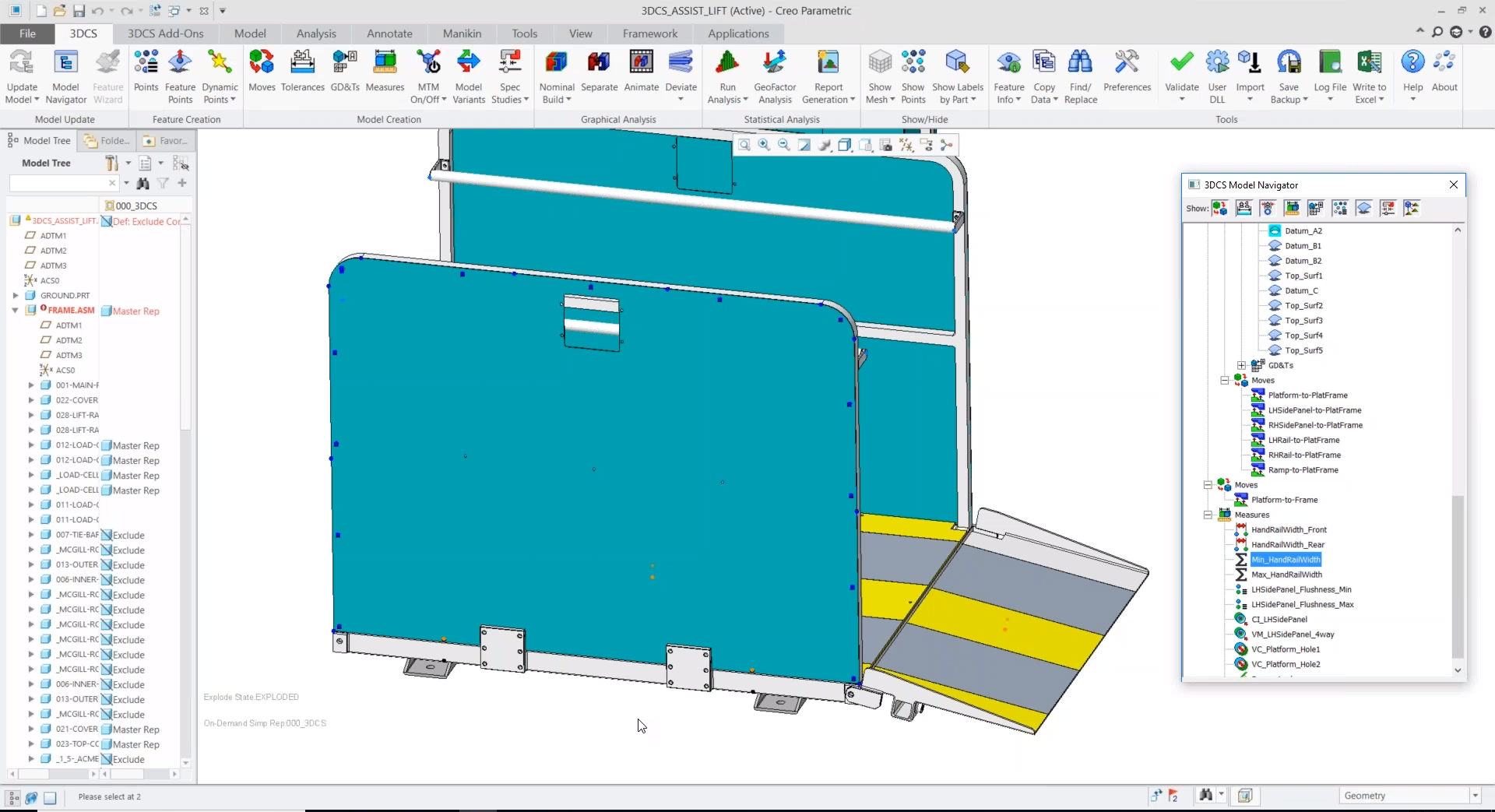

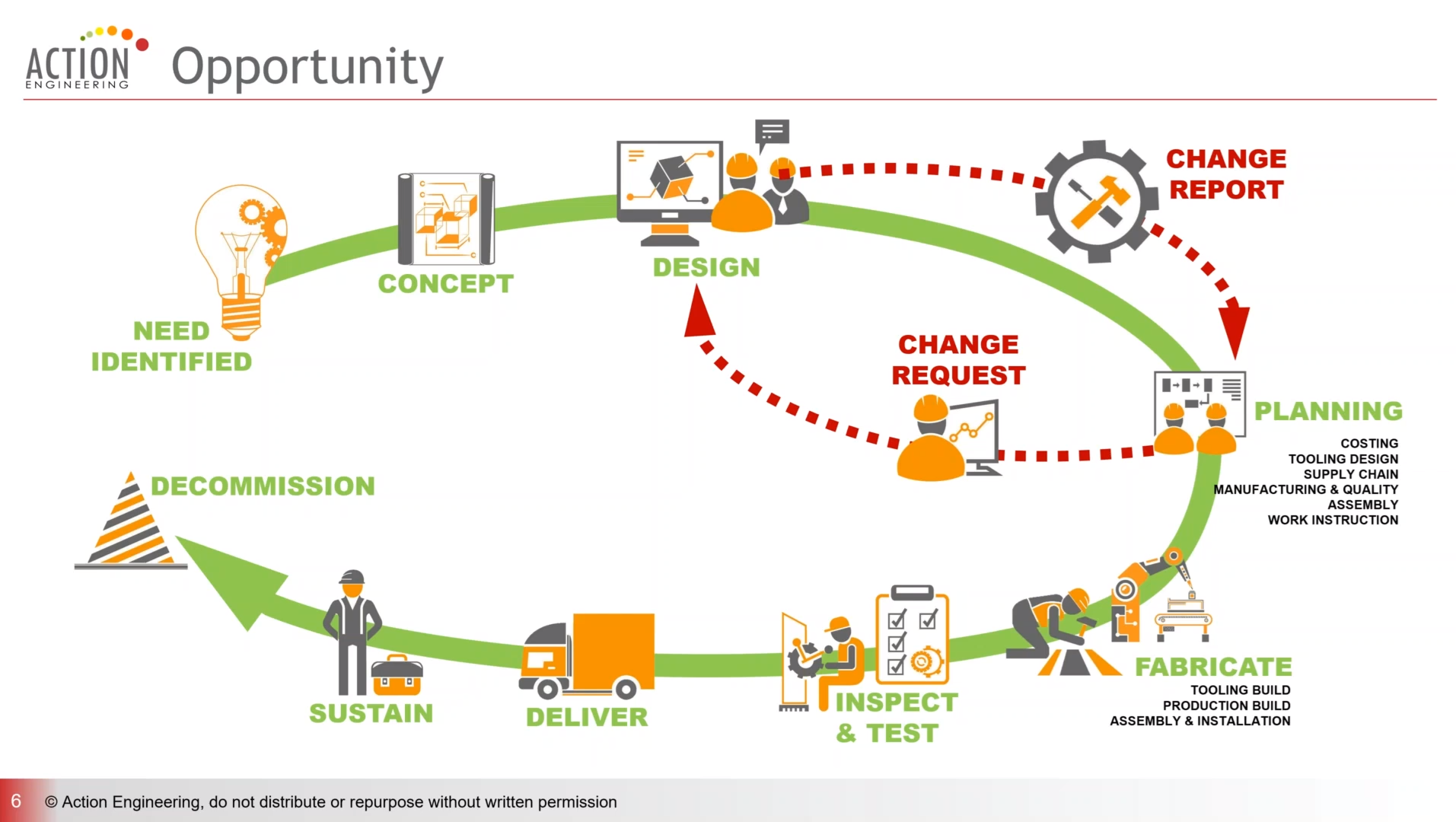

What do you use your model for after your analysis? Find out how to continue to leverage it throughout the product lifecycle

This webinar focuses on what users can do with a model after it has been completed. This includes using Excel and the Process Capability Database to update the model, as well as creating reports and inspection plans from the model results, and different ways to display and present the model.

See how to create measurements to simulate inspection in CAD

Learn tips and best practices when applying tolerances

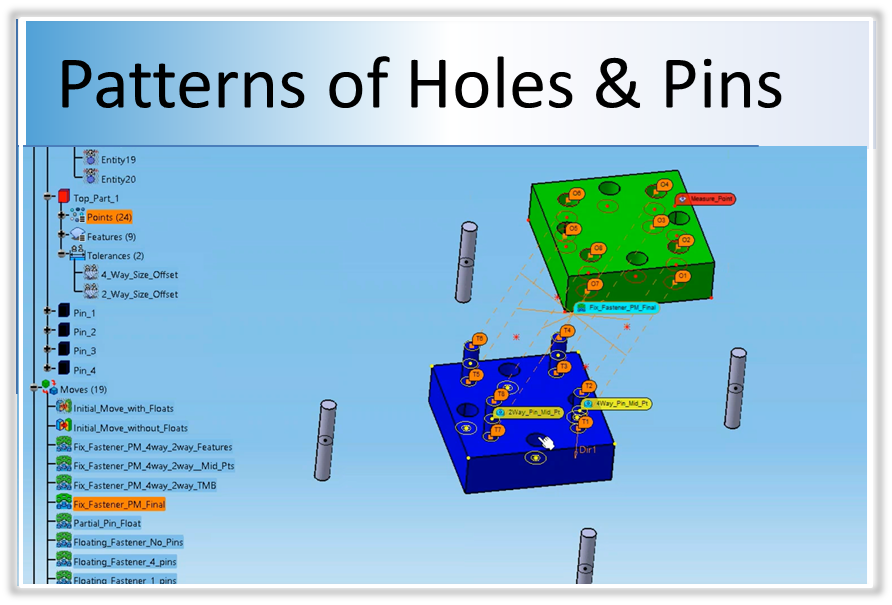

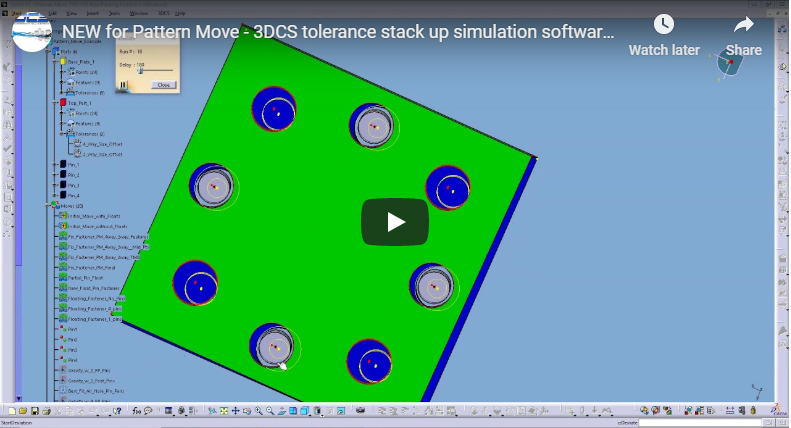

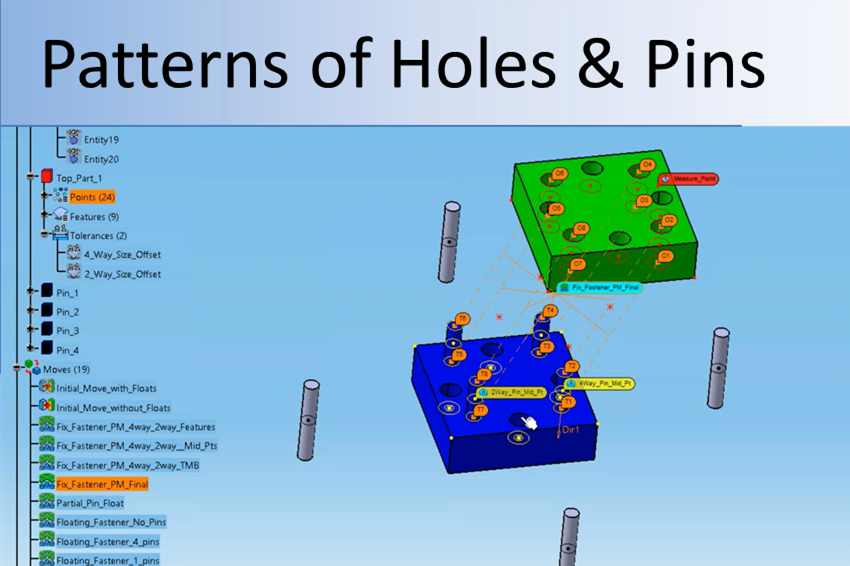

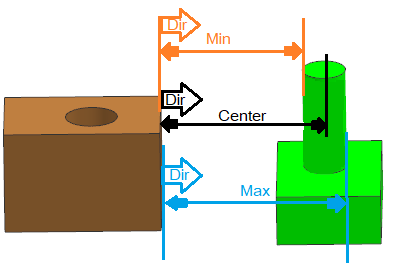

Unique to 3DCS, the Pattern Move allows you to simulate groups of holes and pins.

Plus:

See how Equation Measure can help you get non-standard outputs from your 3DCS model.

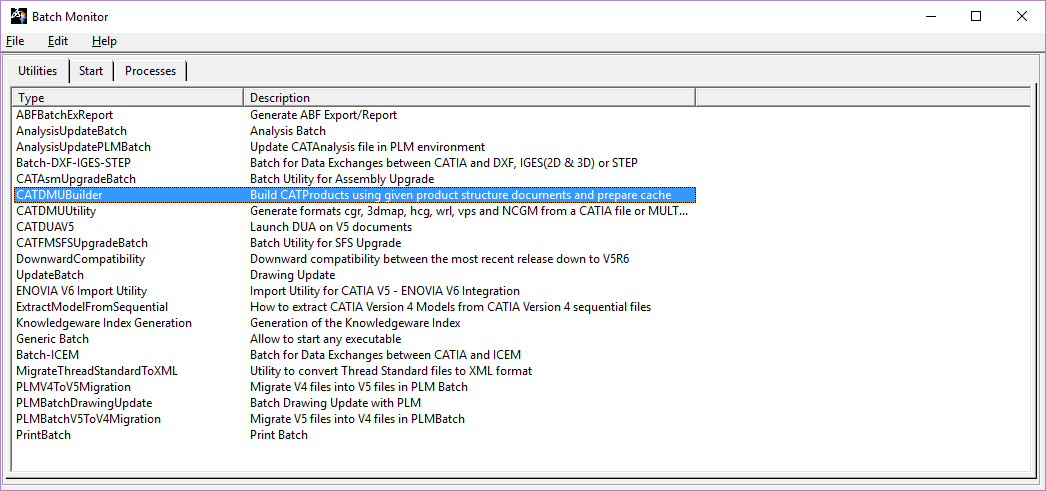

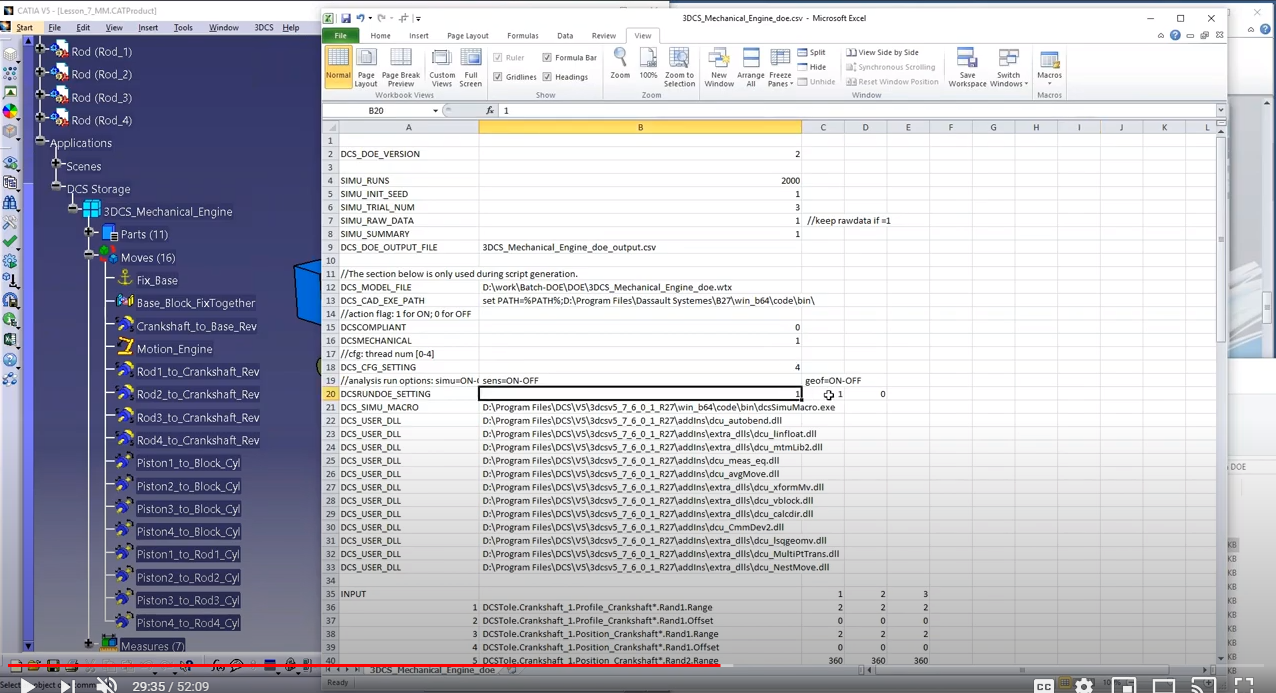

Use the Batch Processor to run analyses in the background or overnight

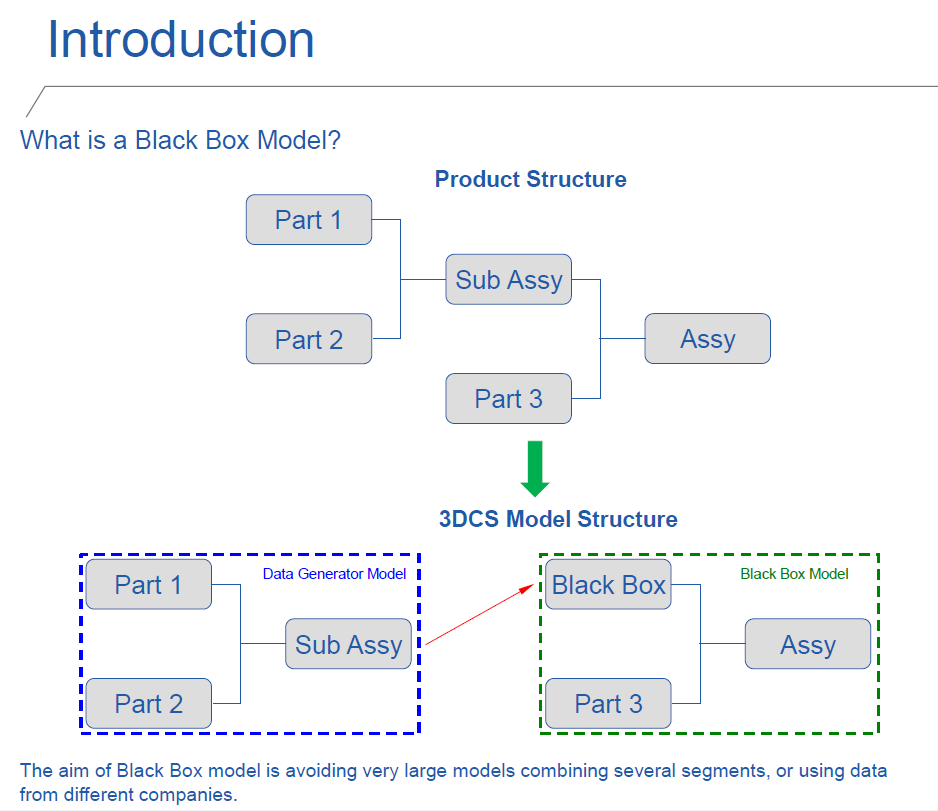

Working With Large Models - Black Box Methodology

Black Box Methodology aims to turn sub-assemblies into single components when working in a model. By analyzing the sub-assembly first, the variation from that assembly can be applied to the overall assembly as a component in a larger structure, such as an aircraft.

This webinar focuses on setting up a 3DCS model, and some Quality of Life techniques you can use to make working on your model easier and faster.

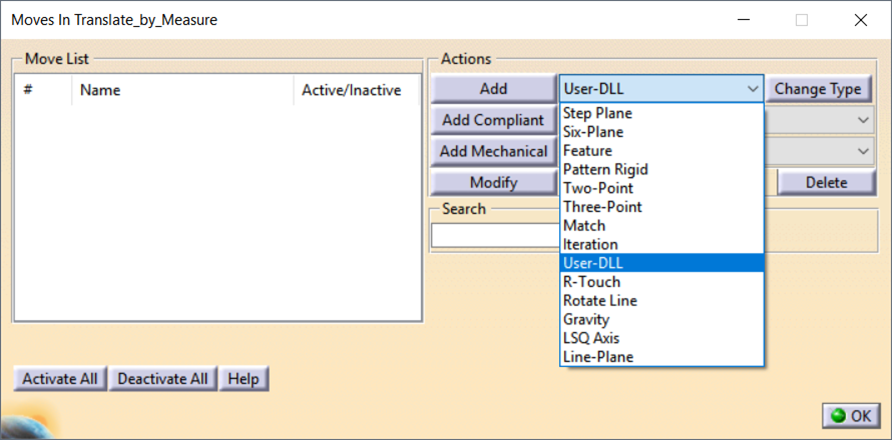

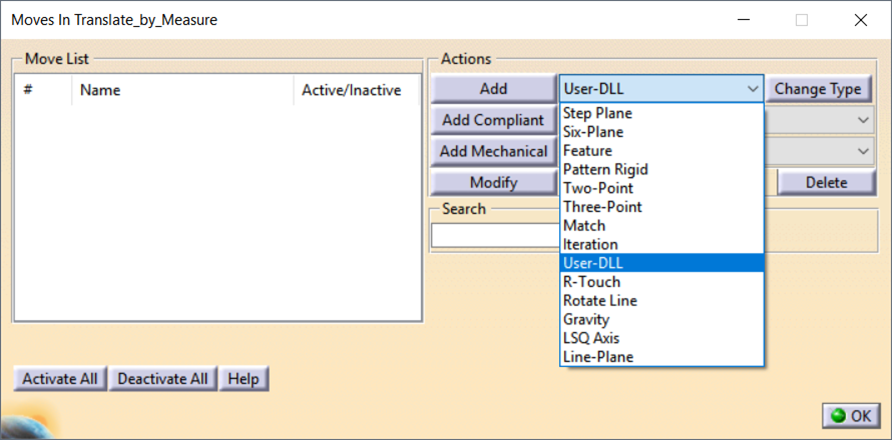

Learn to use the XForm DLL to model special cases, unique moves, and special measure conditions

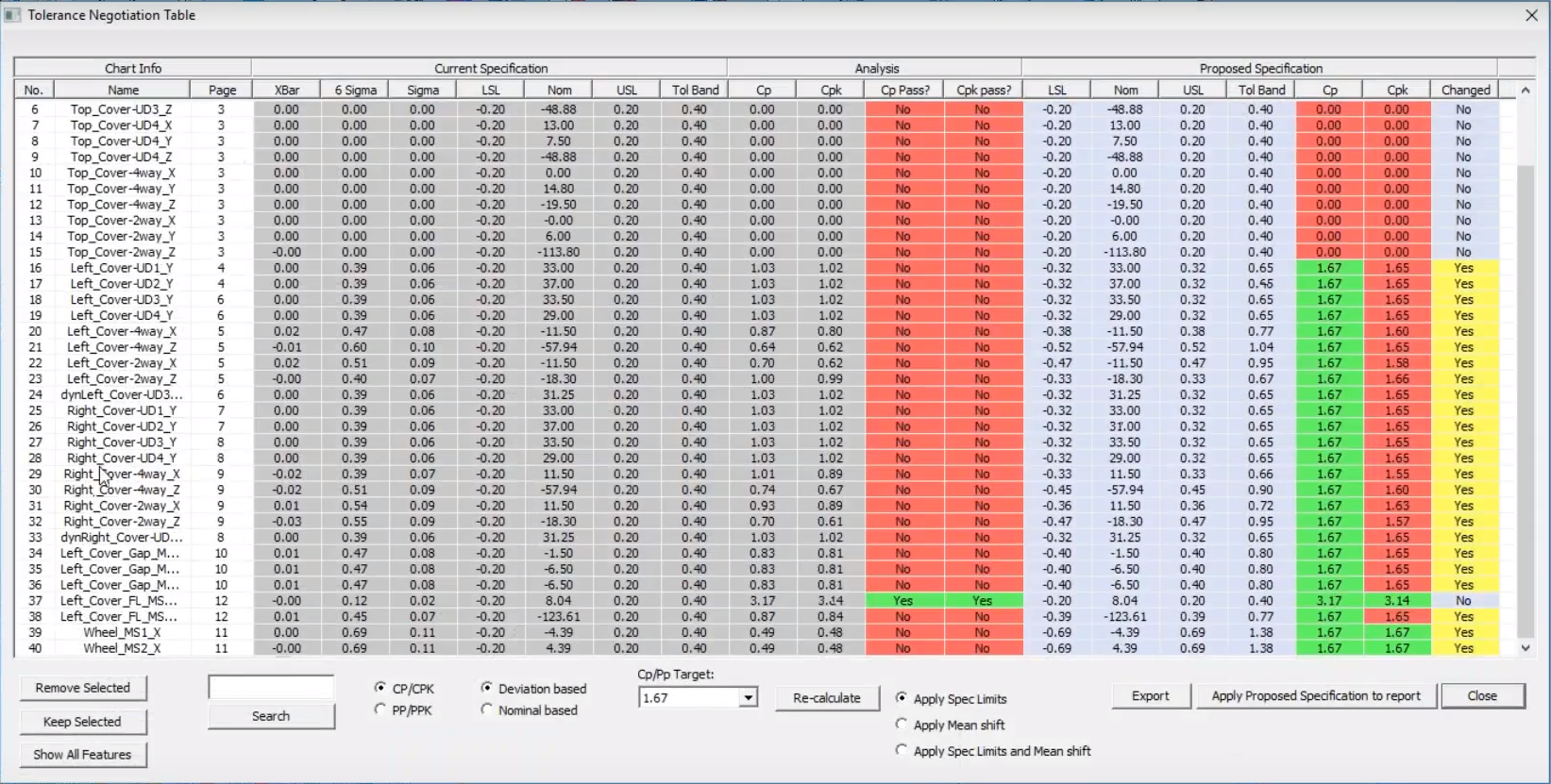

Learn about Tolerance Negotiation, Supplier Quality Standardization and Cloud SPC Systems

Tolerance Negotiation

Plus:

Using QIF to Maintain the Digital Thread from OEM to Supplier

Learn about:

Learn how to utilize your 3DCS model to accomplish a number of tasks and downstream applications such as:

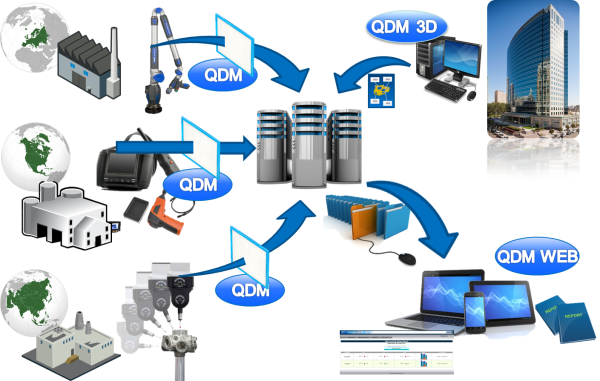

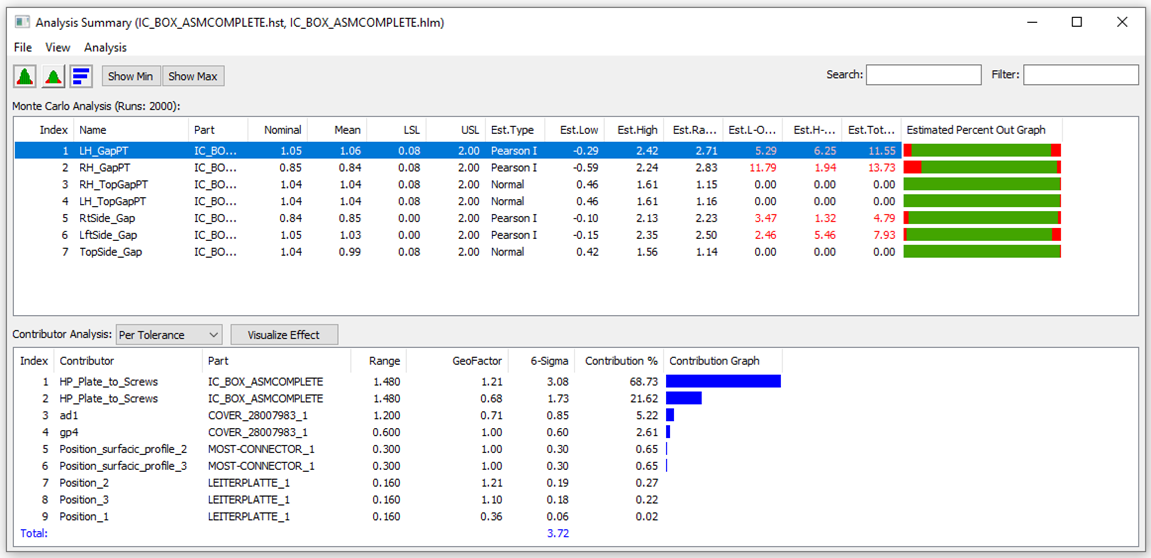

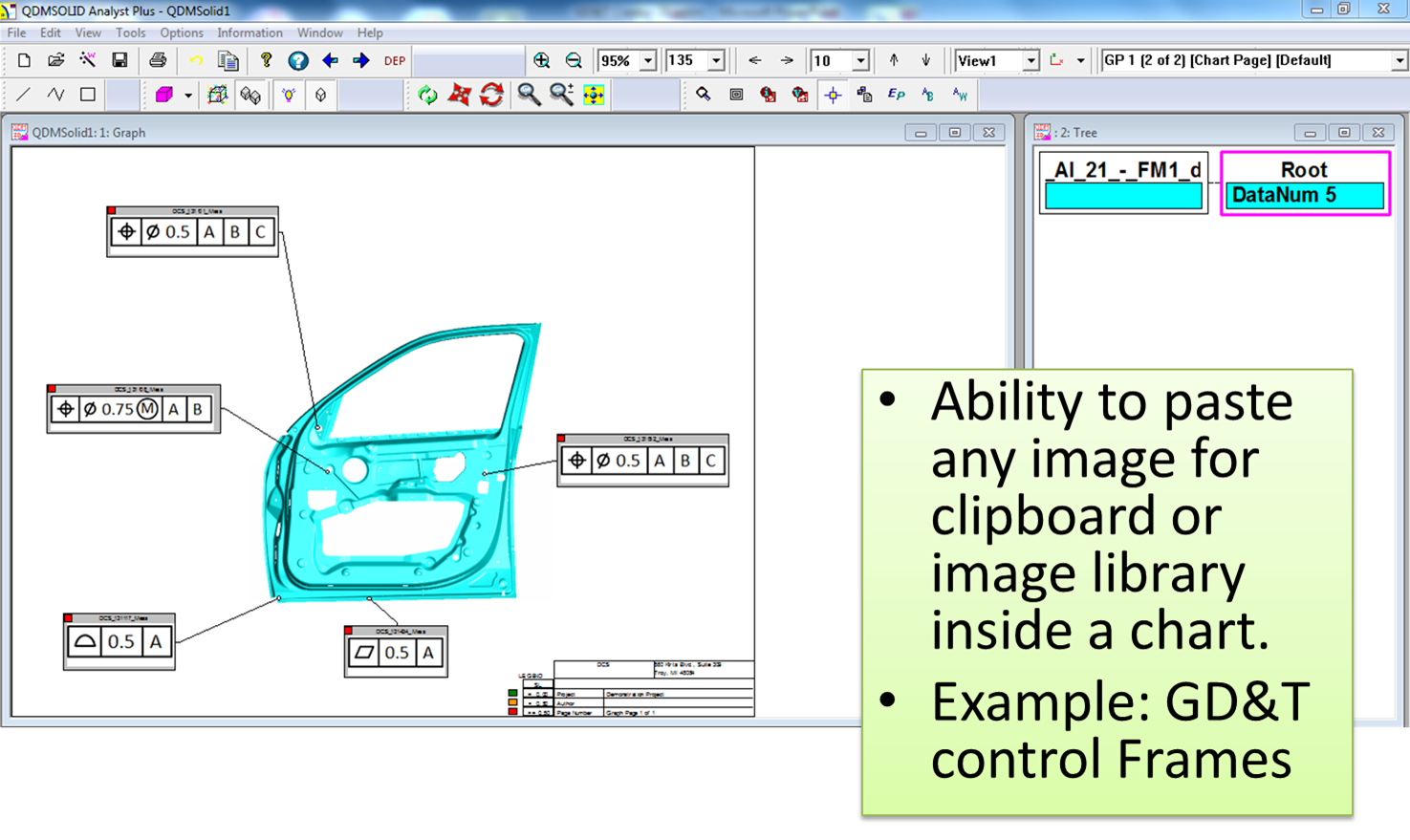

This online training course covered the 5 latest function enhancements and 5 productivity enhancements added in the latest version of QDM (formerly GDM).

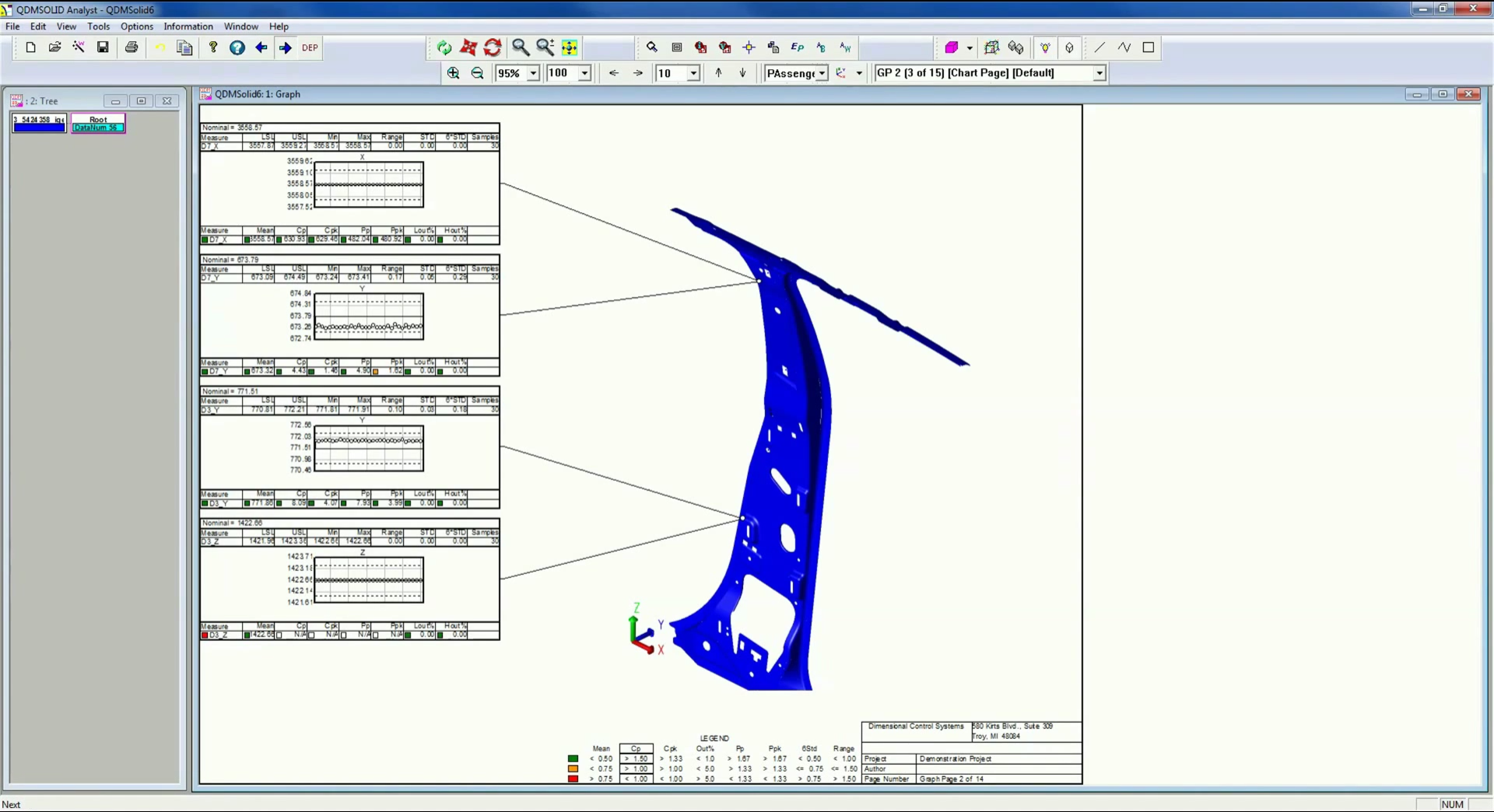

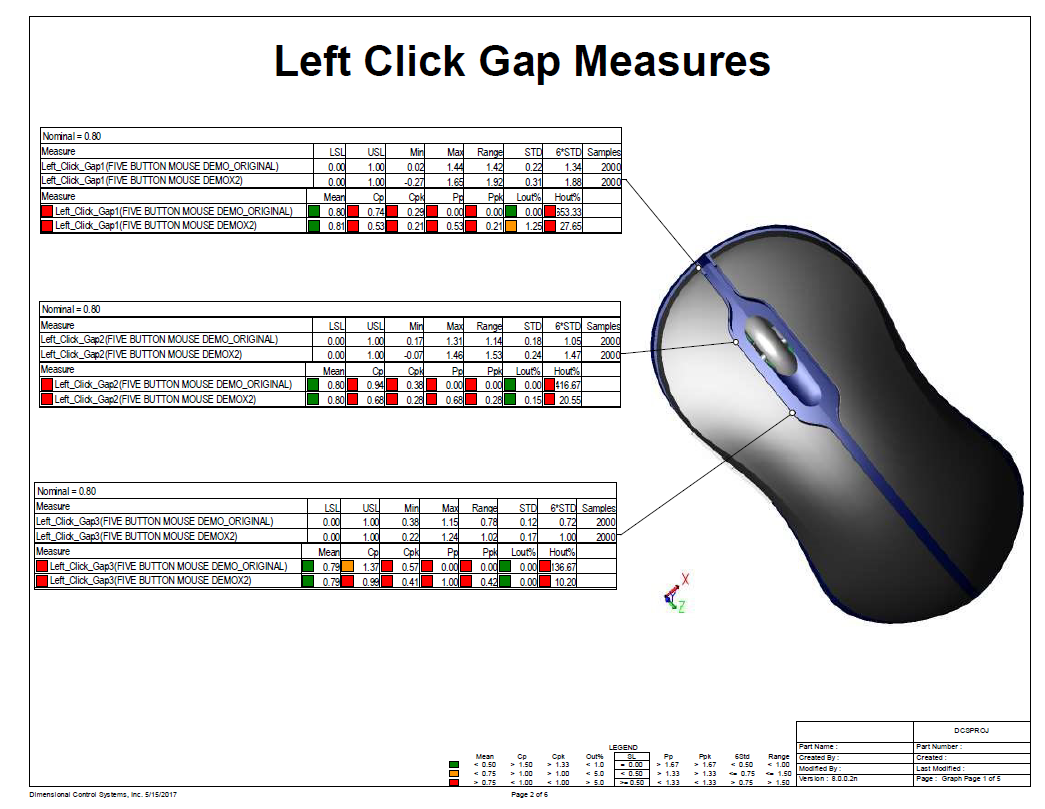

Learn how to use QDM ANALYST to create quality reports from measurement data in seconds.

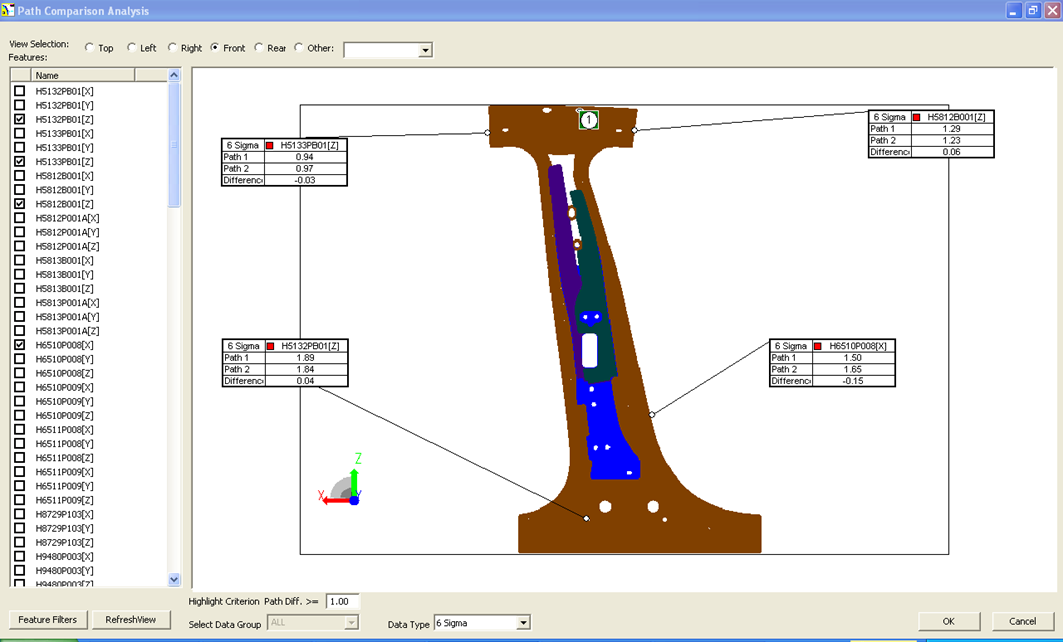

This webinar shows 4 different ways QDM ANALYST, the basic standalone module of QDM for report and template authoring, can be used to compare data sets.

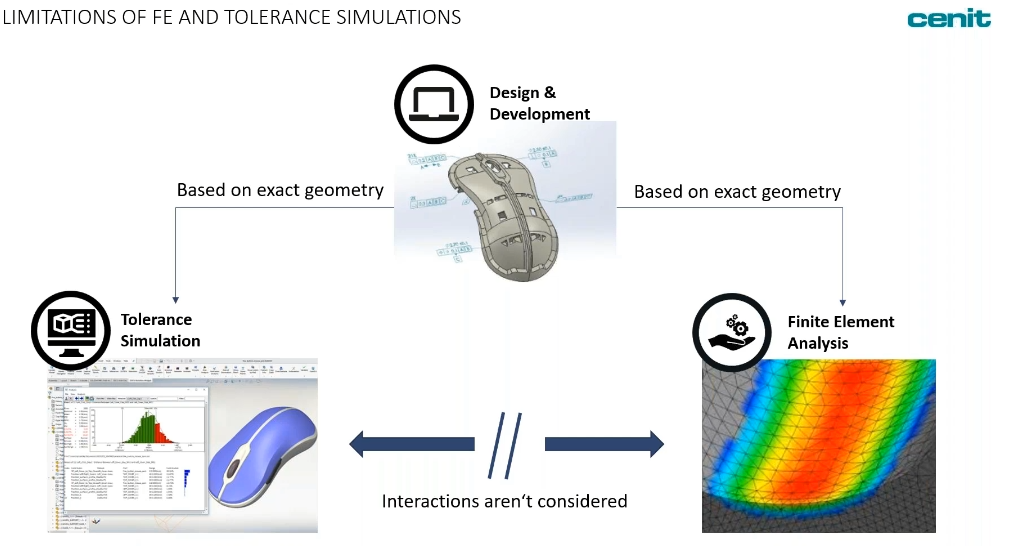

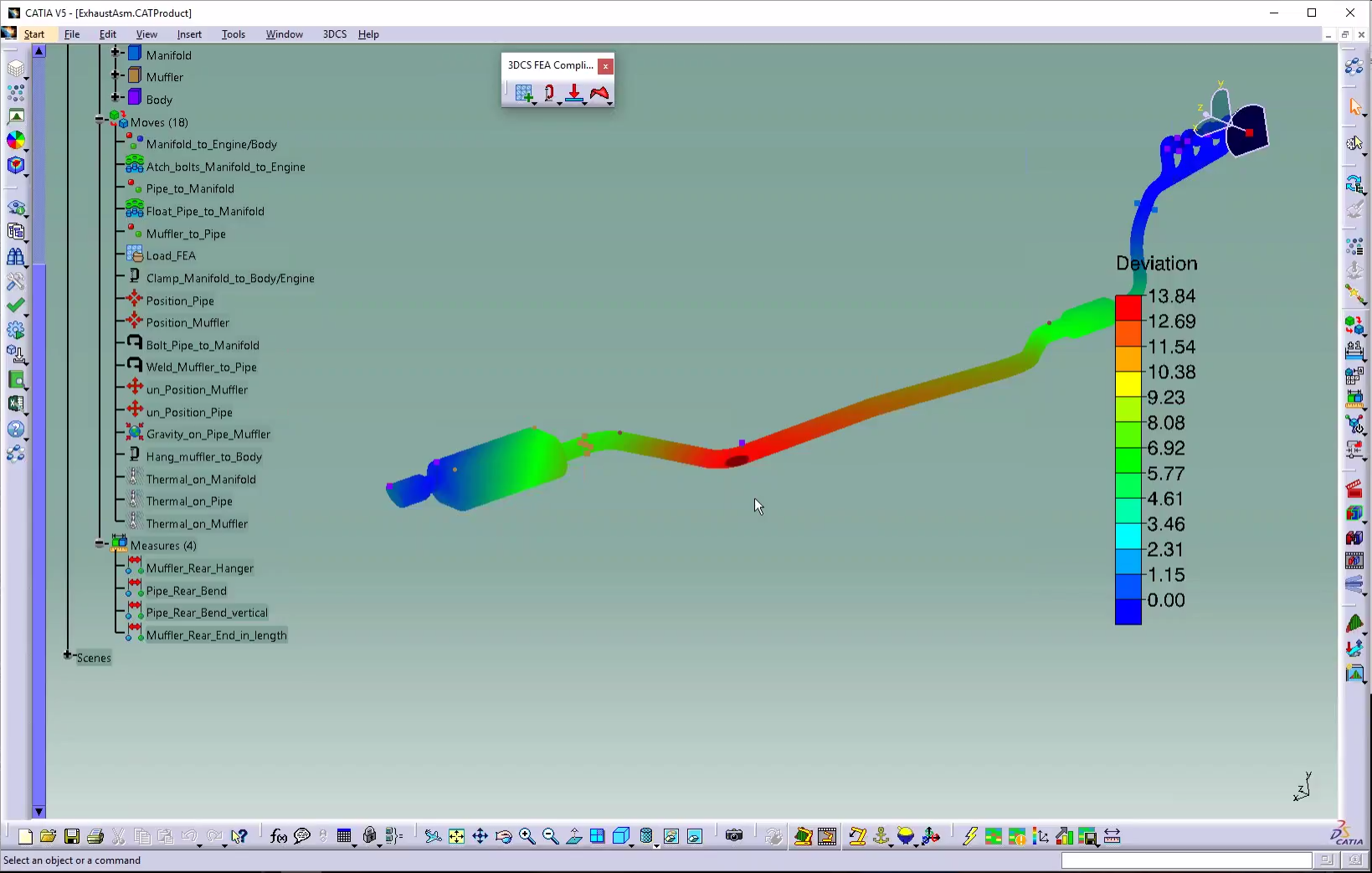

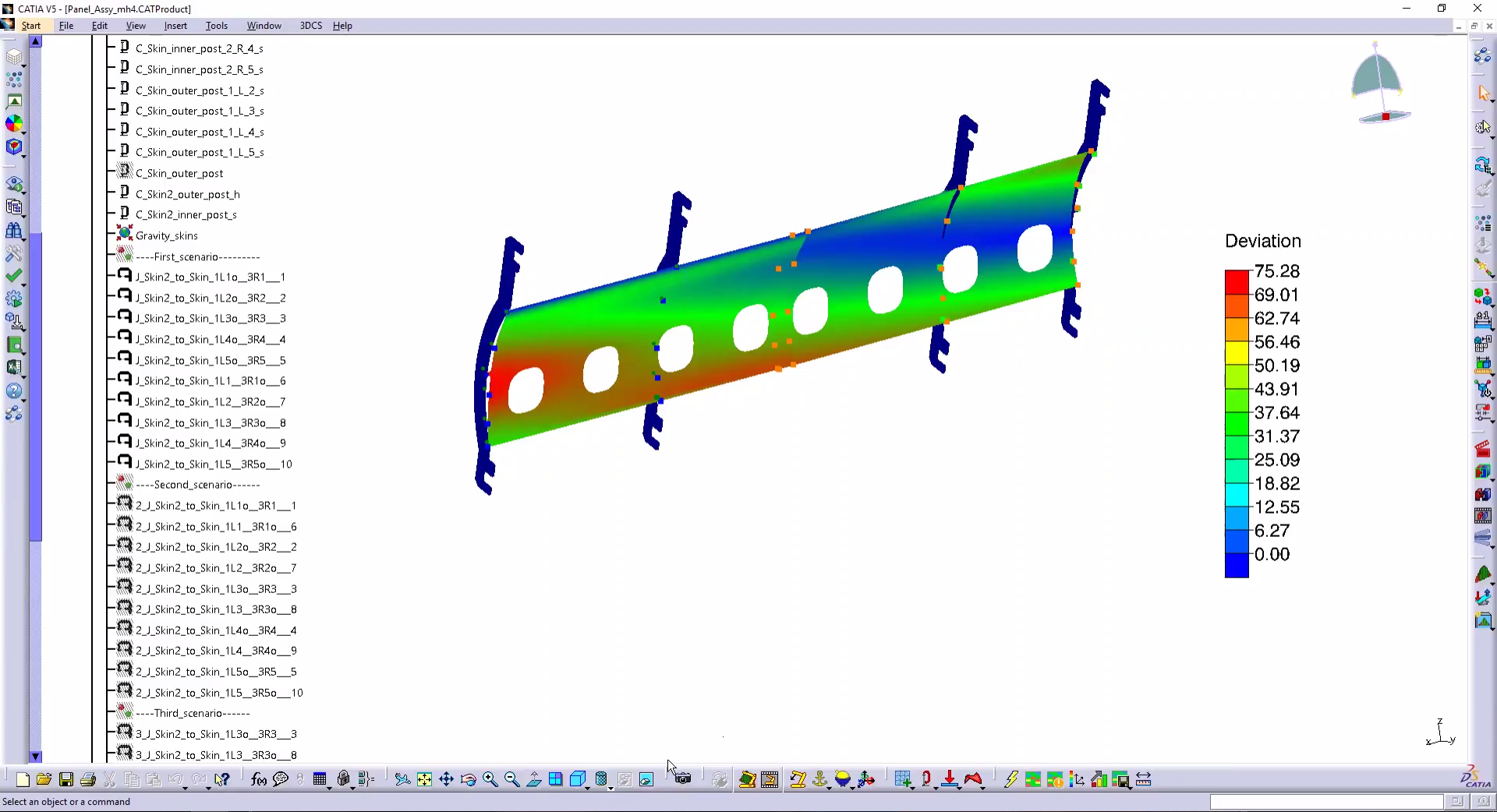

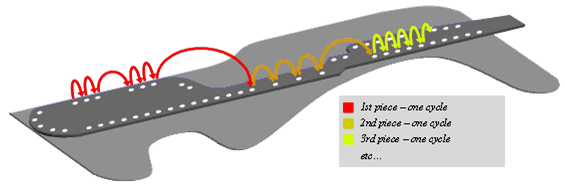

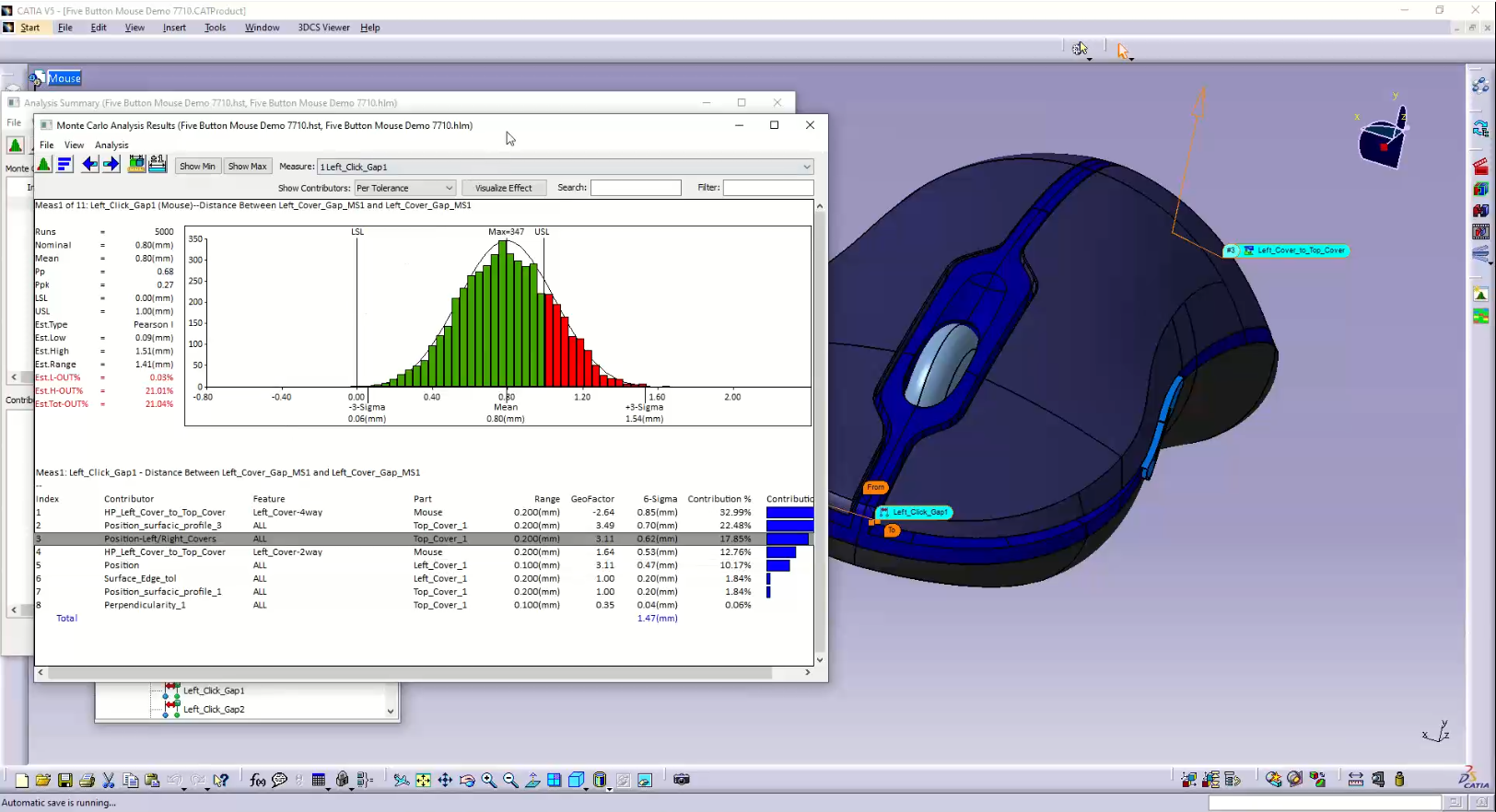

3DCS FEA Compliant Modeler is an add-on module for 3DCS software allowing the incorporation of Finite Element Analysis.

Just some of the things you can do with Compliant Modeler:

See 3 Methods of improving supplier quality by incorporating suppliers into an SPC process. Improve data communication, document control, data flow, and validate supplier parts before they leave the plant.

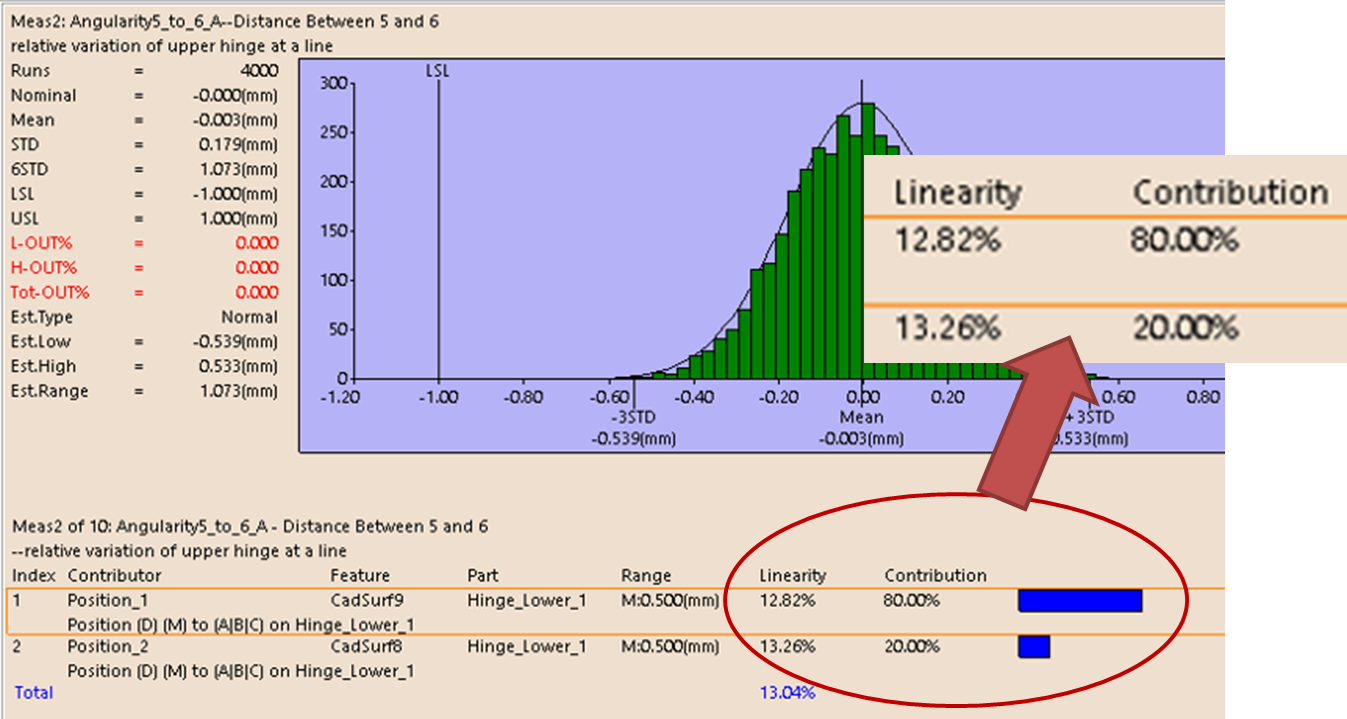

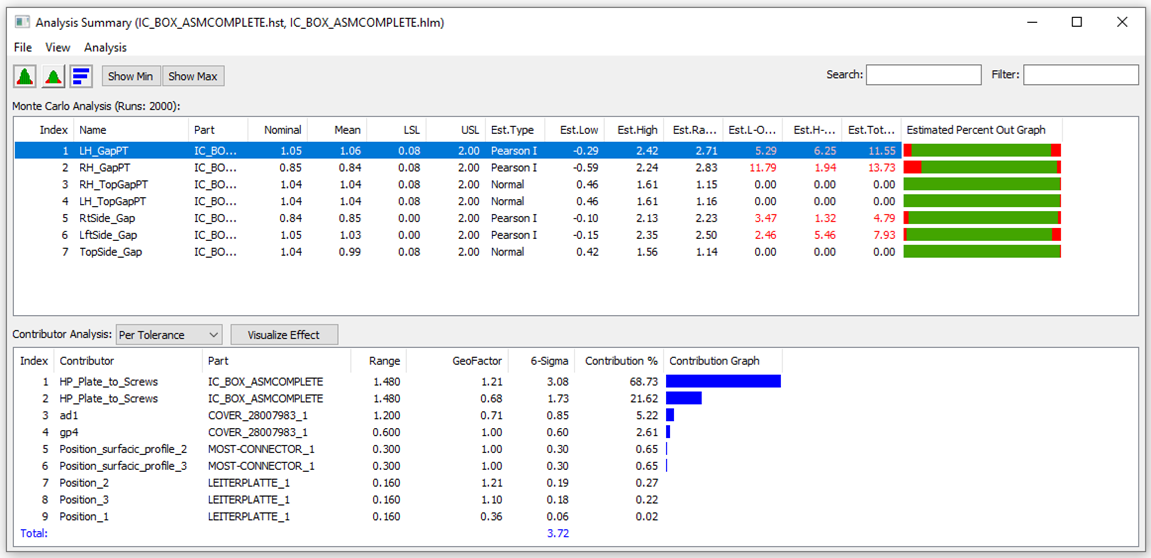

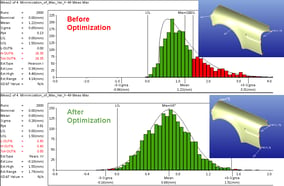

1. Advanced Analyzer Matrix – display all of your tolerances or measurements in a single table to quickly view outputs, statistics, and make changes globally.

2. Critical Tolerance Identifier – Find the most critical tolerances in your model or the most critical part in your assembly that adds the greatest variation.

3. Tolerance Optimizer – Optimize your tolerances instantly to meets specified criteria, loosening non-critical areas, and tightening critical ones.

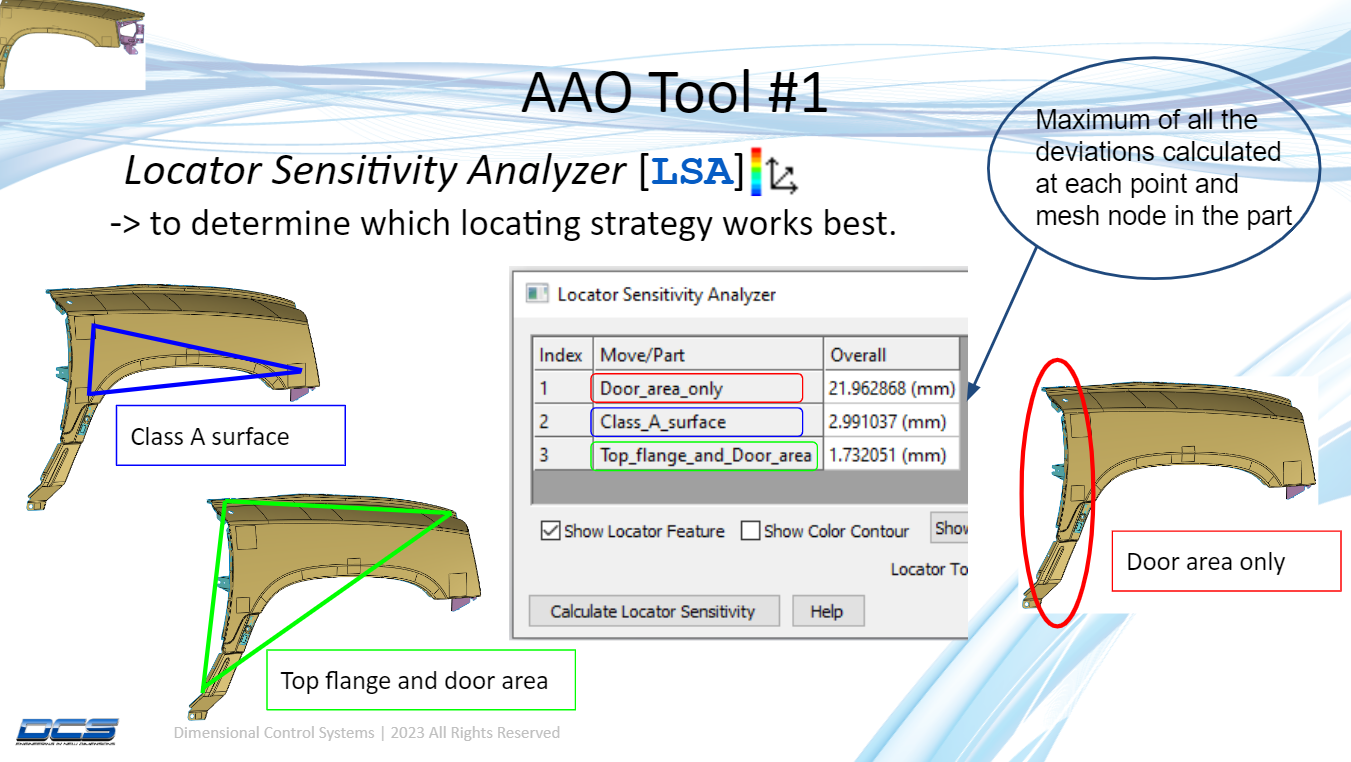

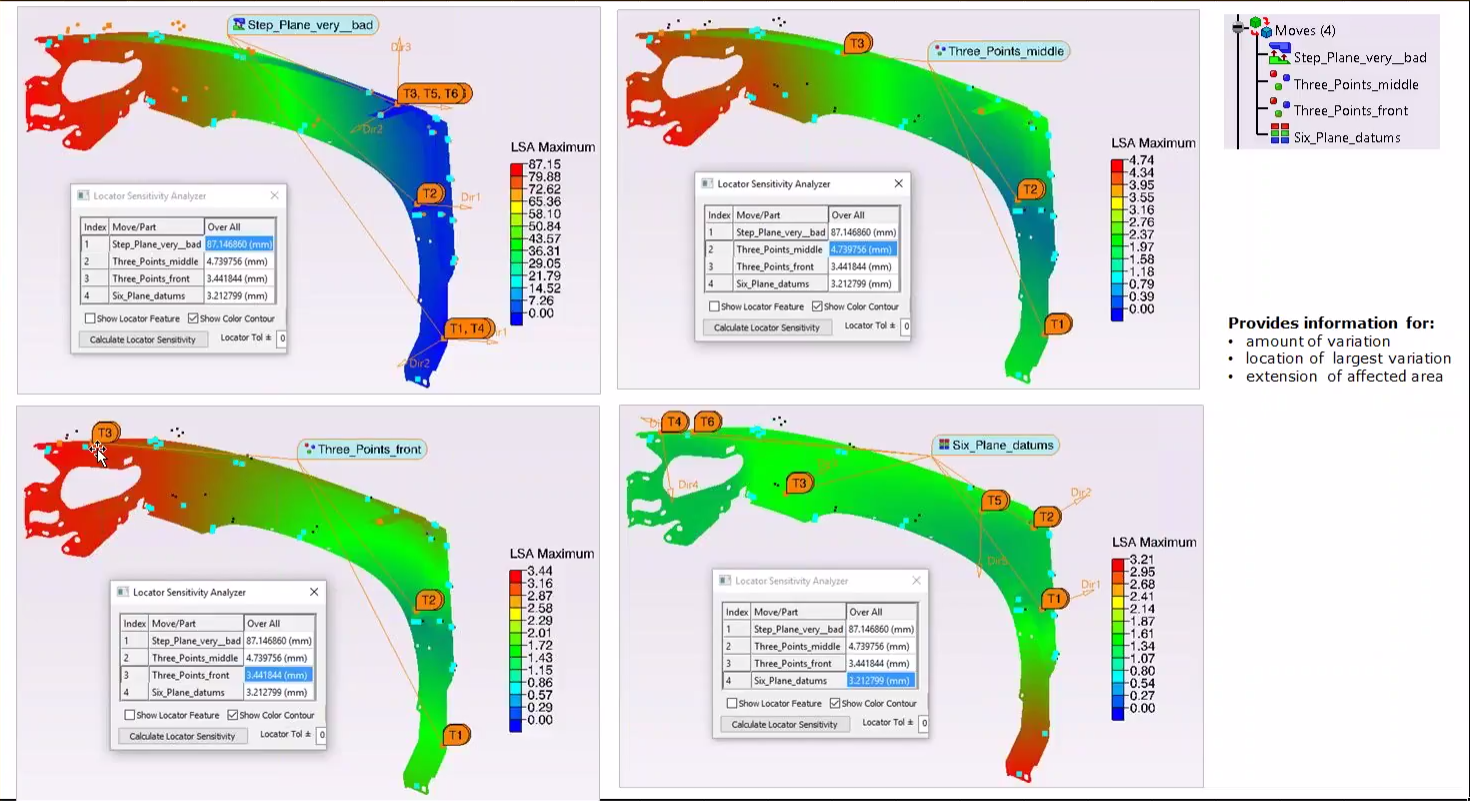

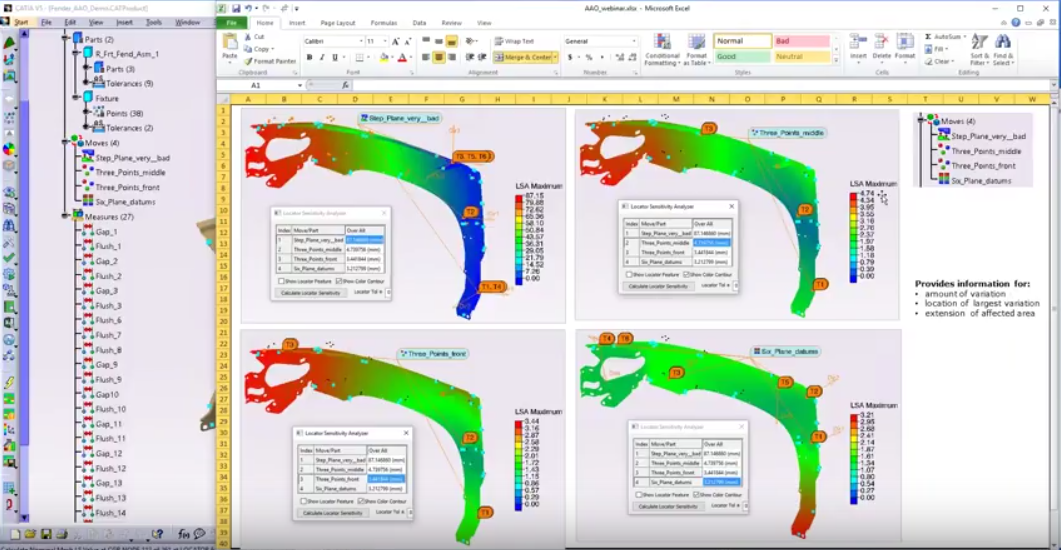

4. Locator Sensitivity Analyzer – Use LSA to check and validate moves, tooling, and locator strategies.

Part two is for advanced applications. Optimize assembly processes, the order of operations, and locations for processes. How many clamps do you need? Where is the best place to put them? Will the order of welds affect the assembly differently? Advanced applications for optimization will be covered in part 2 of the webinar.

Simulation Based Sensitivity (SBS) is a new advanced analysis tool coming out for 3DCS Advanced Analyzer and Optimizer Add-on (AAO) for all versions of 3DCS software.

Use SBS when:

Two great new features now available in AAO and the core software, LSA and Alias Display are great for testing your model for functionality and quickly naming or re-naming your points and moves. View the webinar to learn more!

Take aways:

Showcasing the new 3DCS for NX product in the NX Platform, this is an excellent webinar for new and experienced 3DCS users looking to use NX and 3DCS together.

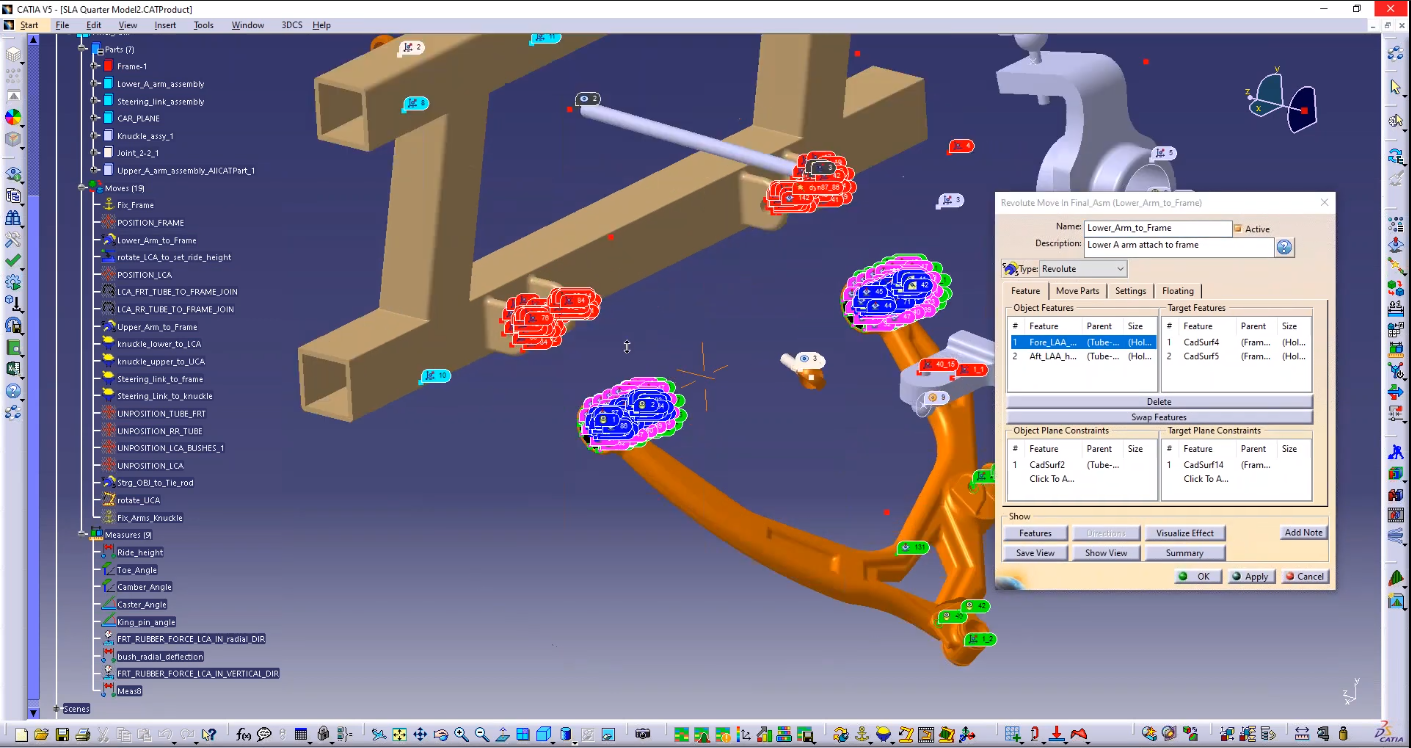

Learn how to use Joints and Constraints in your tolerance stack up.

Learn how to use the new GD&T interface and new methodology of adding tolerances in 3DCS

The new interface offers:

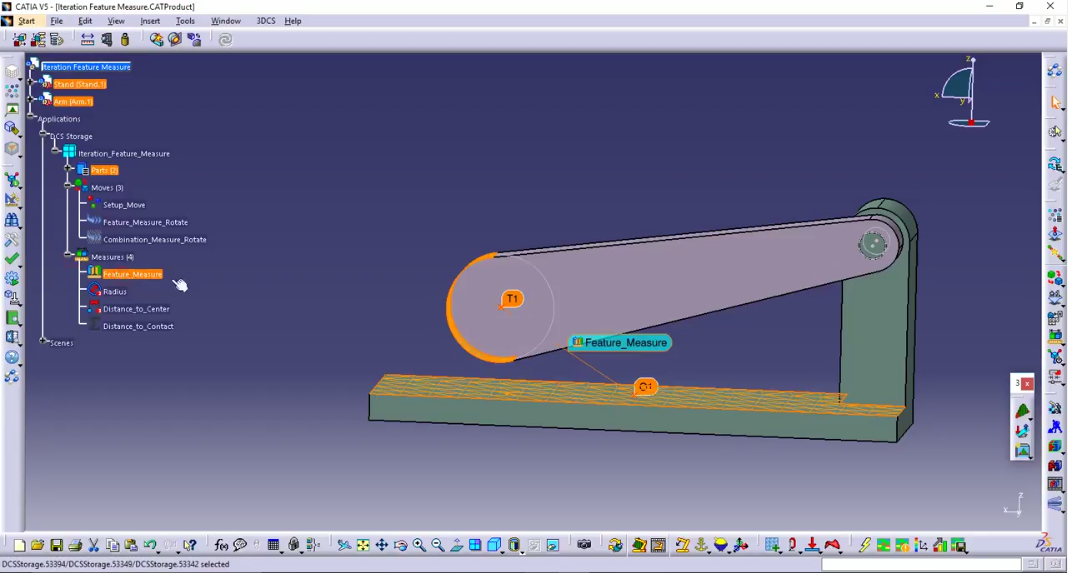

Learn from Srinivasrao Balaga, DCS Senior Dimensional Engineer how to combine mechanical kinematics and compliant FEA moves together into a single assembly.

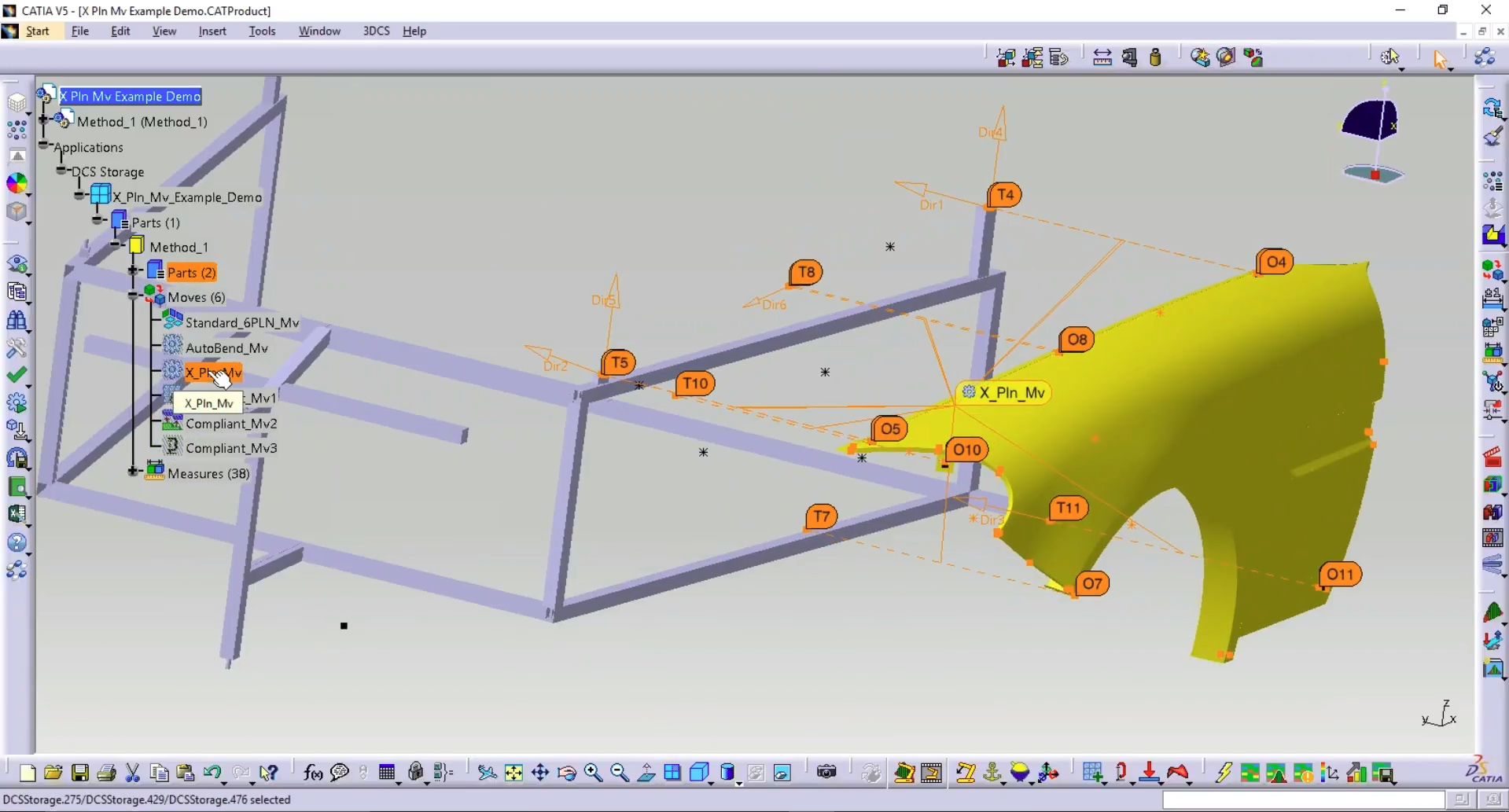

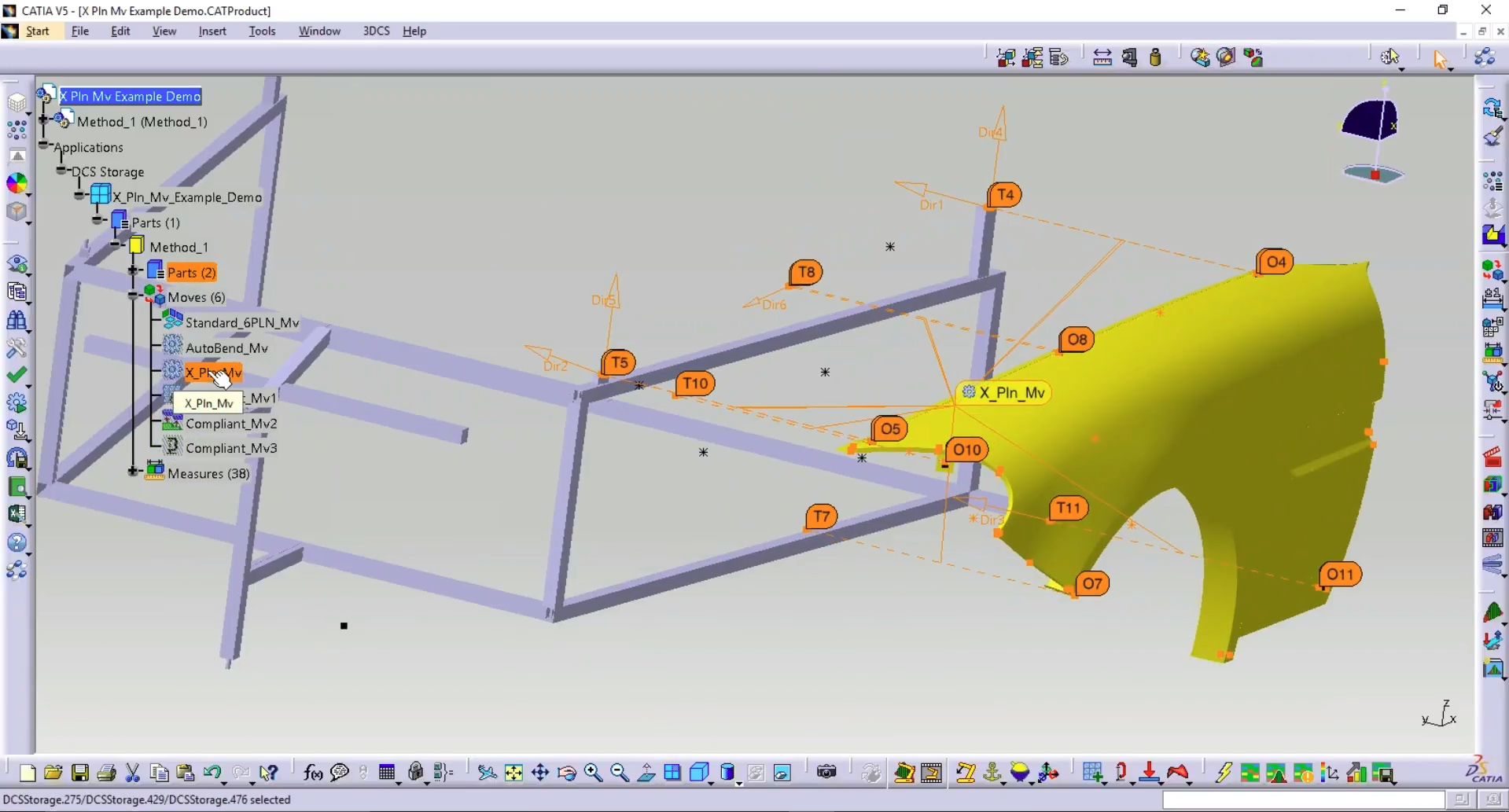

The X-Plane move is a 6-Plane move that allows for more than six pairs of features to be selected and then best fits your parts. It is a powerful move that can be used in a large variety of situations and may become your go to move for modeling in 3DCS. Learn how to use it, and see a number of example models to start using this new move.

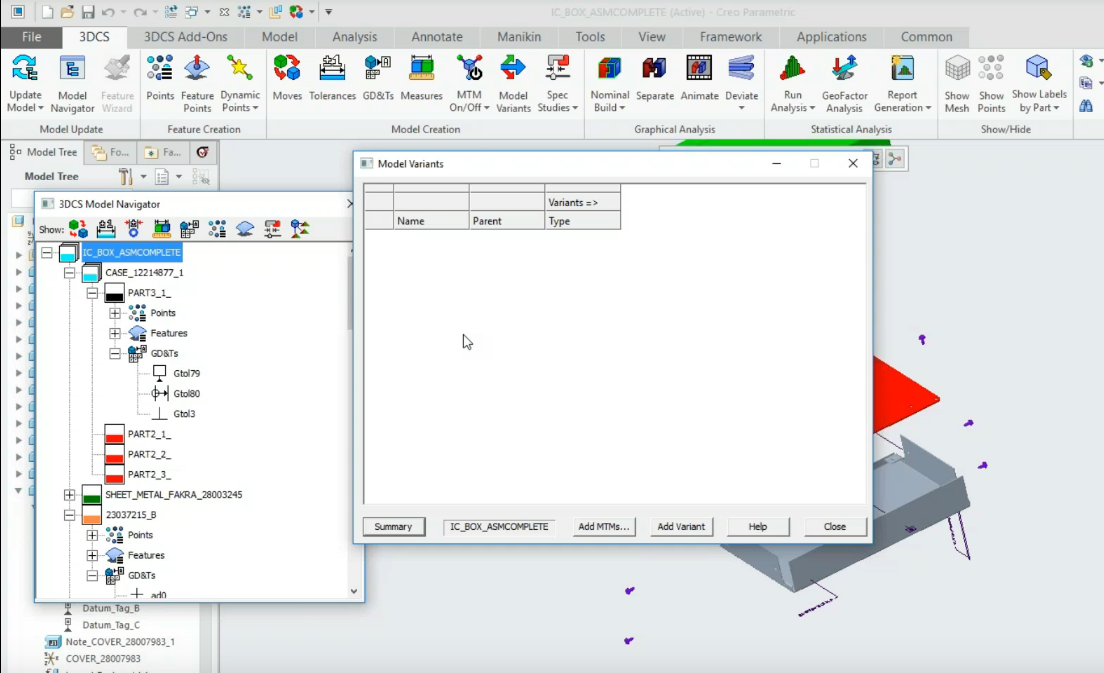

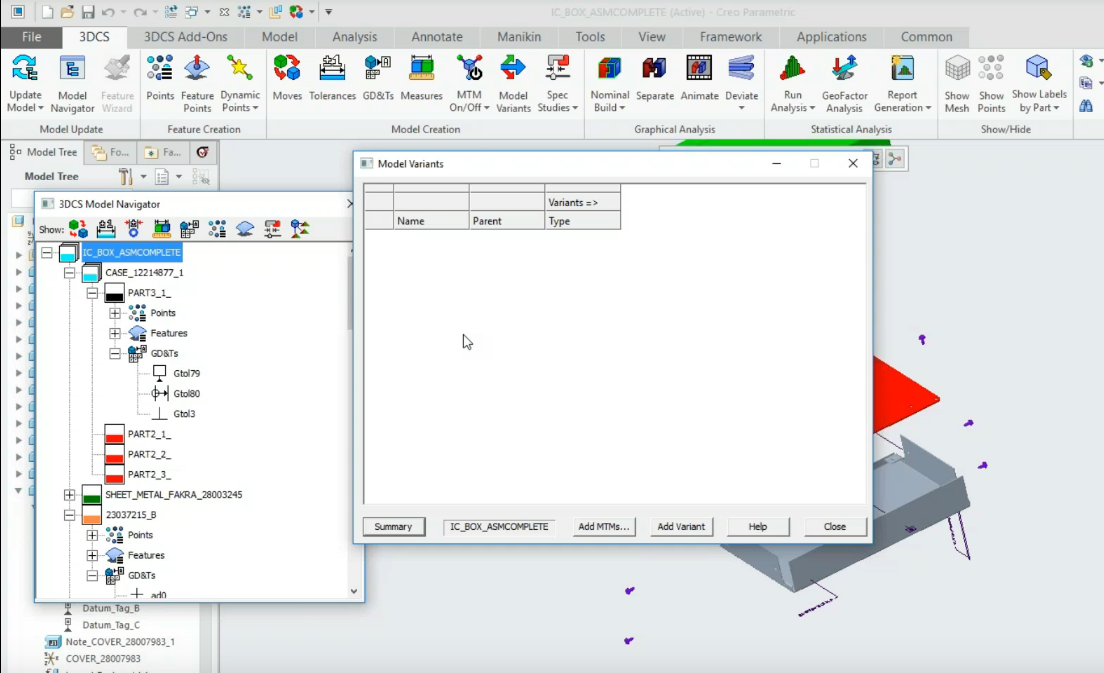

Understand and learn how to use Model Variants as well as Show Samples in your Analysis output

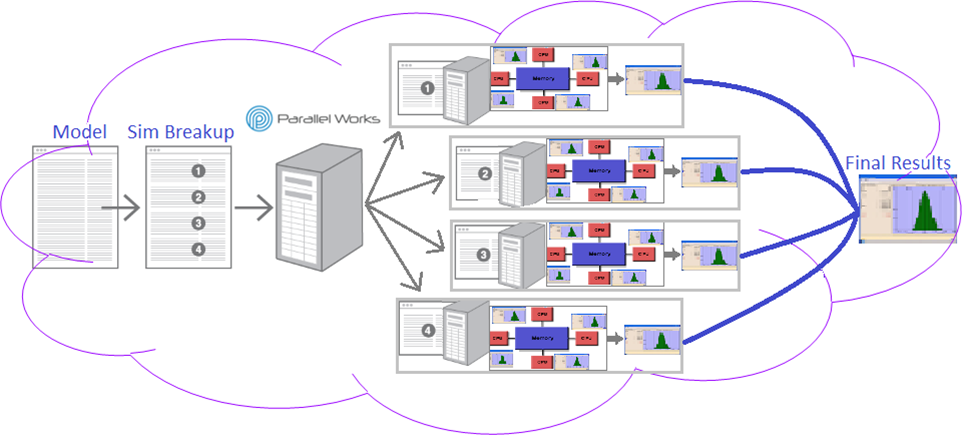

DCS is adding two new features to 3DCS that will greatly decrease your analysis time, getting you the answers you need faster than ever before.

DCS and Bordrin New Energy Vehicle Company discuss the steps leading up and including modeling in 3DCS software

Take Aways:

Take Aways:

Take Aways:

Take aways:

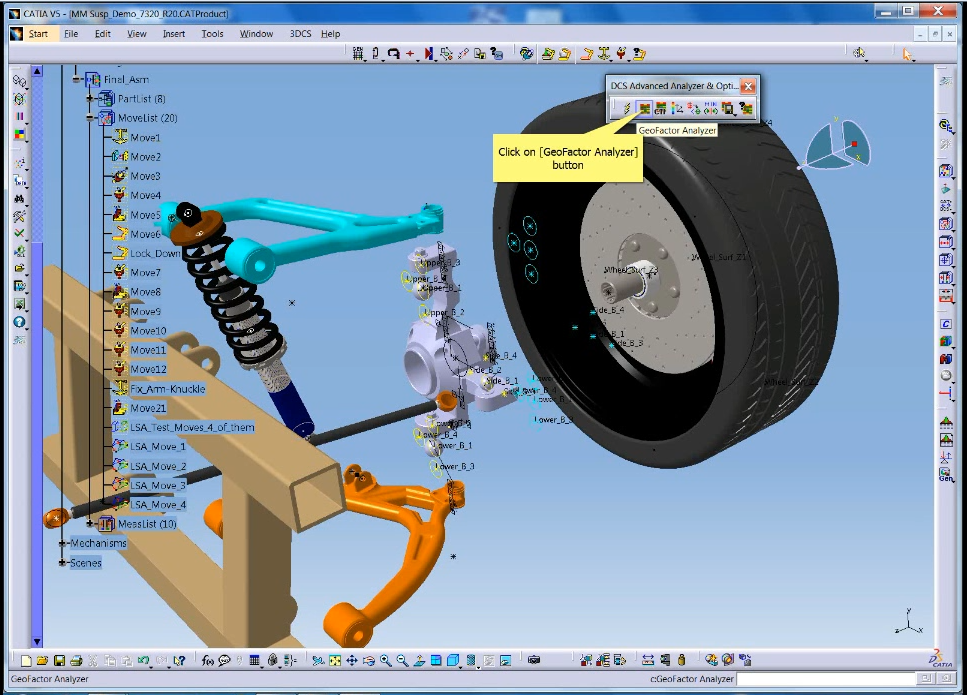

Learn about the new features in 3DCS version 7.7 including the new Table View, Integrated GeoFactor and Tree Groups

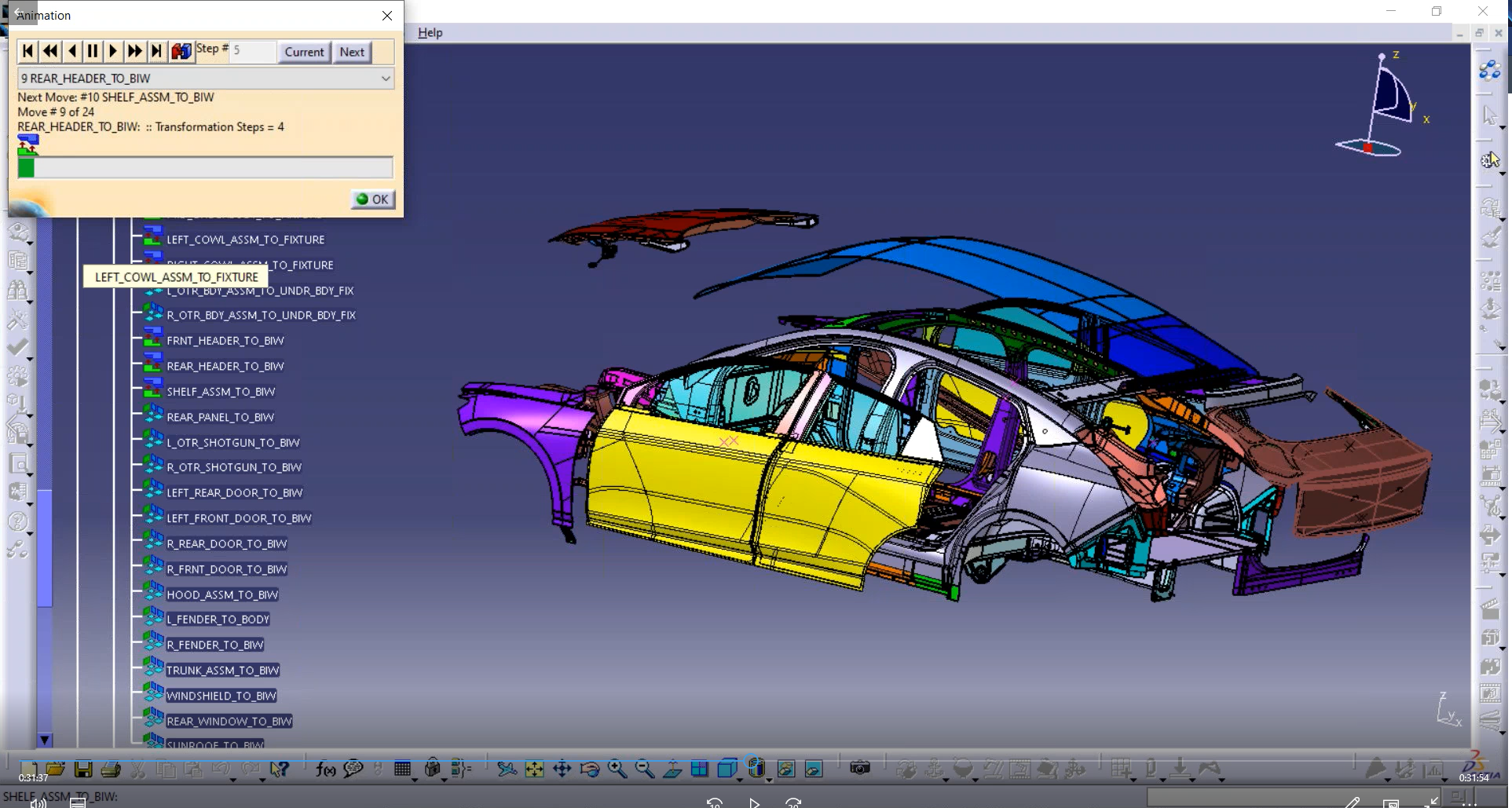

3DCS fully integrated in CATIA 3DEXPERIENCE

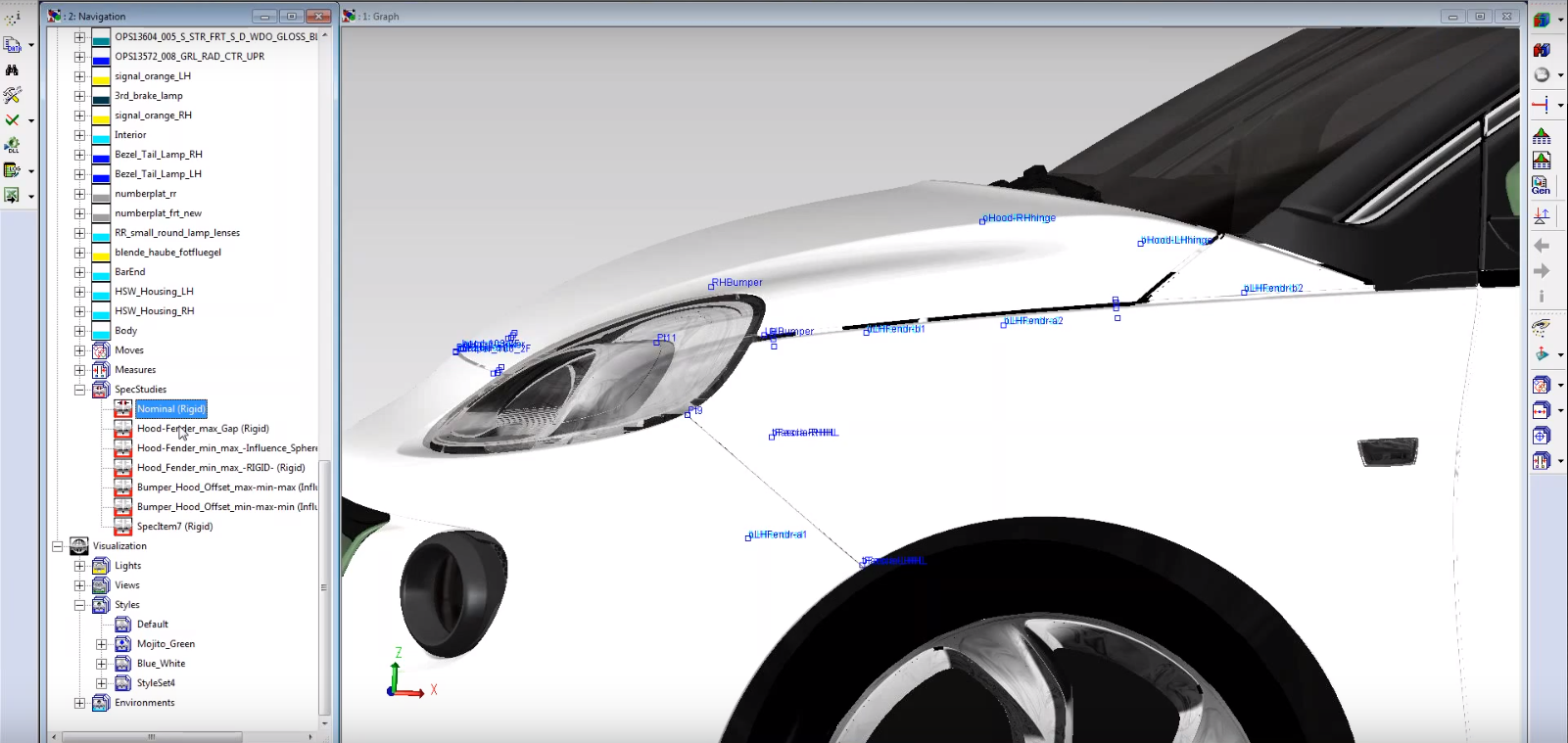

Guest presenter Daniel Dresemann, Dassault Systemes, showcased Live Rendering and 3DCS for 3DEXPERIENCE to communicate quality between Design and Manufacturing

Learn about the new features in 3DCS version 7.7 including GD&T Measure, and enhancements to both X-Plane Move and the Pattern Move.

Reduce Cycle and Launch Time by Optimizing Clamp, Join, and Weld Sequences

Requires AAO Add-on module

Understand the process and value of Dimensional Management through a combination of helpful storytelling and examples

Learn:

QDM 3D Analyst has been expanded on in the new Version 8.1 Release.

This release compiles all of the updates, enhancements, and new features added over the last 12 months to make it easy to utilize in your quality reporting and SPC studies.

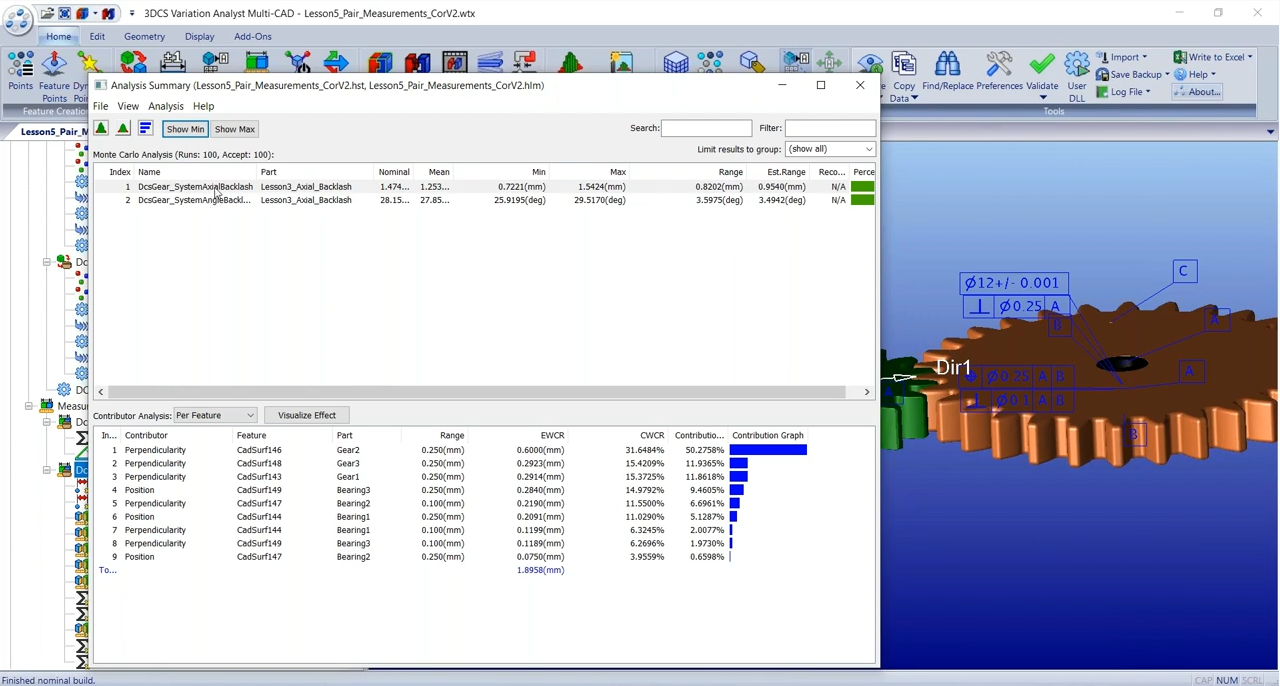

Learn how 3DCS can assess gear backlash and mounting misalignment, perform angular backlash analysis, and create flank test displays and contact patterns. Here are some of the measurements it supports:

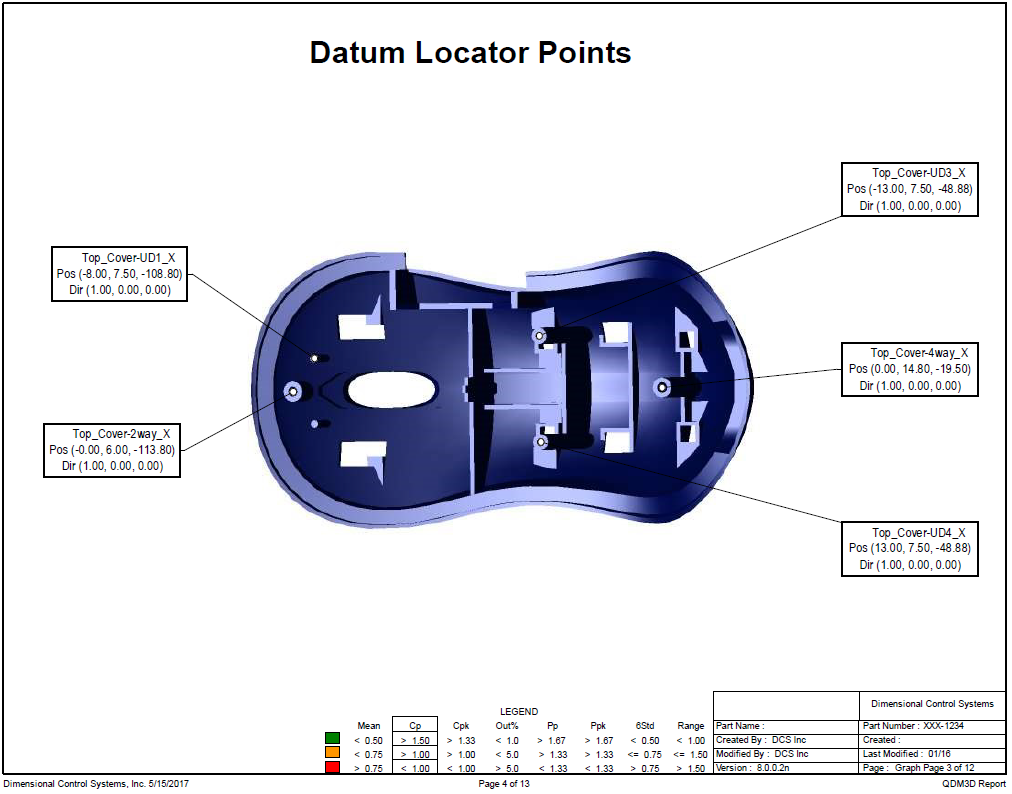

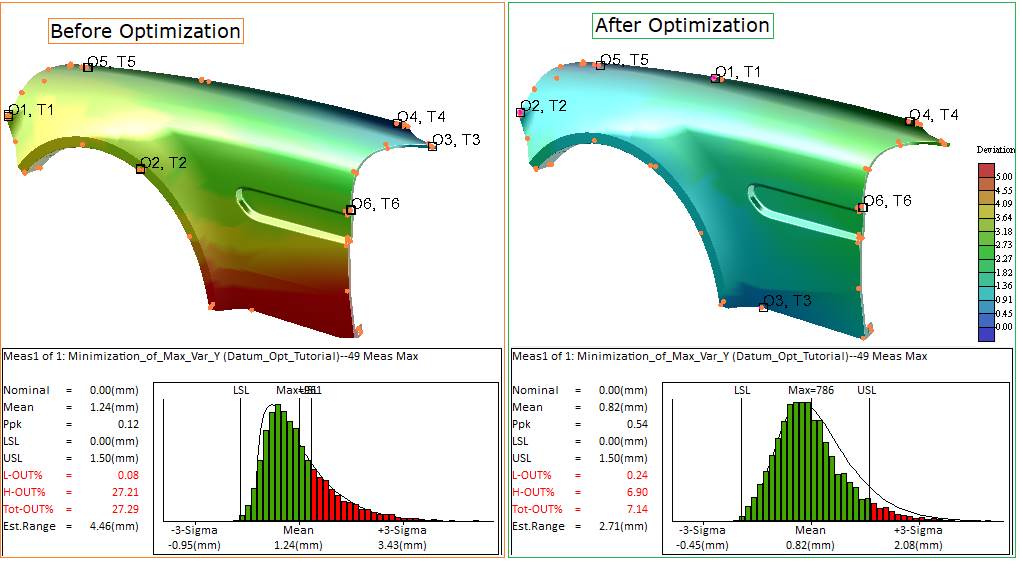

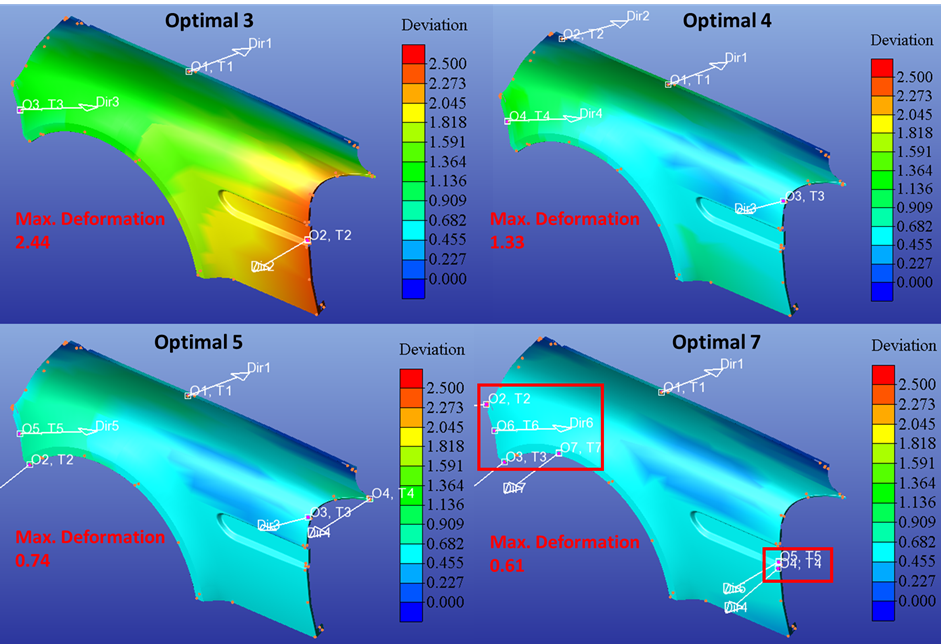

The NEW 3DCS Datum Optimizer is a tool using a genetic algorithm to determine the optimal datum features from a candidate set with the goal of minimizing the rigid part variation or compliant part deformation.

The new release of 3DCS provides some great enhancements and tools:

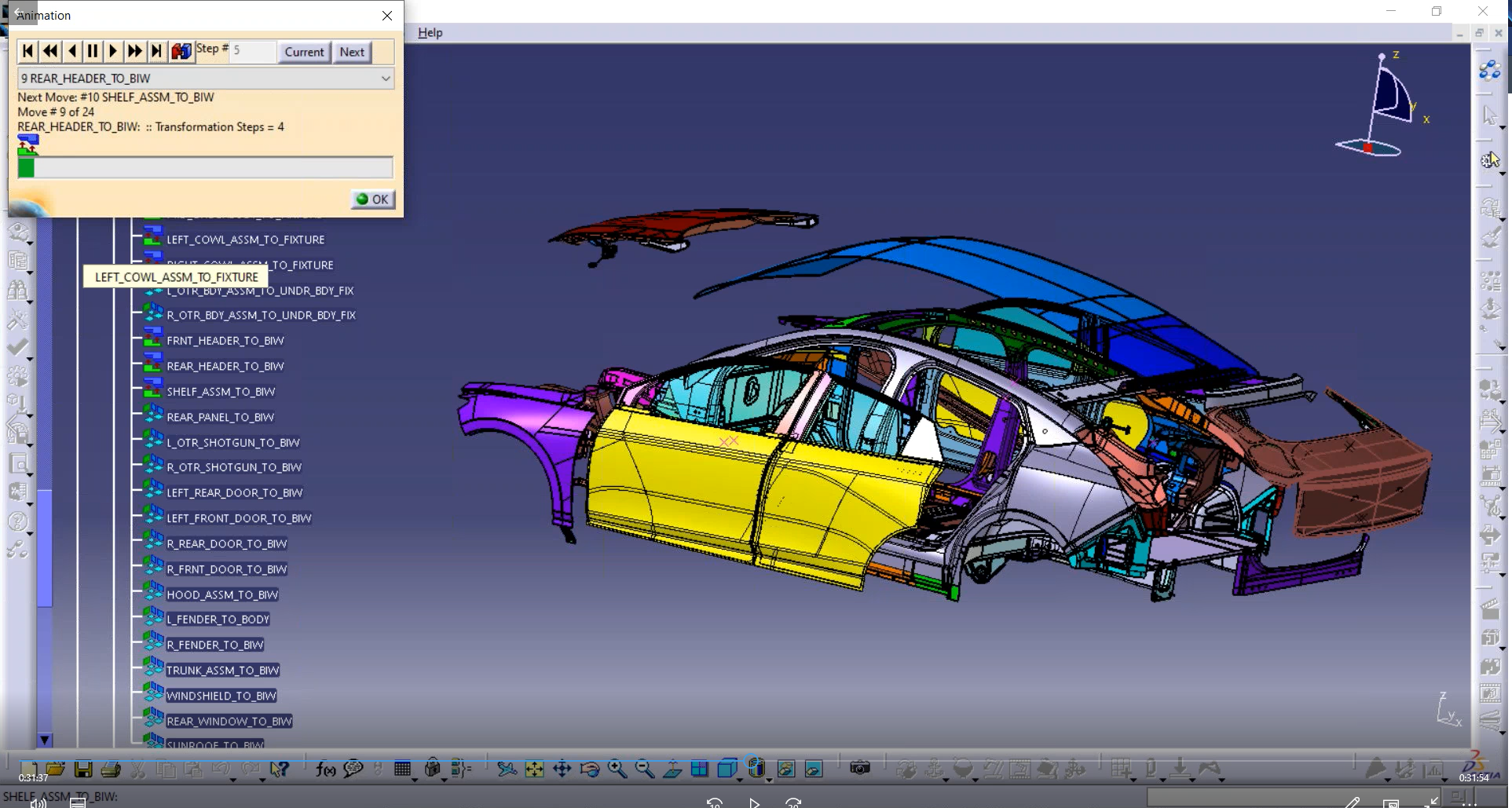

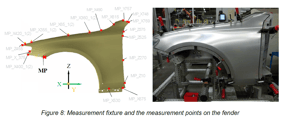

DCS is proud to present guest speaker Hanchen Zheng, Daimler. Zheng will be discussing the process, inputs, and results from his validation study on 3DCS FEA Compliant Modeler on BIW parts.

This paper proposes an approach to implement tolerance simulation for a compliant assembly, which includes manufacturing processes such as clinching, bolting and hemming by applying tolerance simulation tool.

Improper selection of datum features during manufacturing and assembly may cause severe quality problems. Improper datum features risk turning all the quality parts, accurate dimensioning and tolerancing, and first-class operations into a defective assembly.

Learn how to optimize datum features to improve manufacture and assembly.

2021 - February

Learn about the new tool for interrogating and viewing 3DCS models, expanding tolerance analysis access across your organization

2021 - January

Learn about the new version of 3DCS specifically created to be easy to use, fast, and more efficient than Excel tolerance stacks

2019 - January

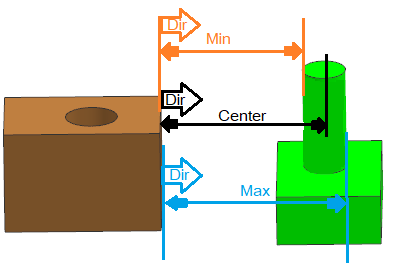

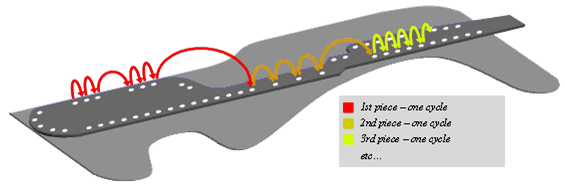

The purpose of the Pattern Rigid Move is to assemble two rigid parts that use patterns of pins and holes as the secondary and tertiary locators. When Nominal Build is performed, the move routine will fit together the patterns of holes and pins.

2019 - February

Replacing Feature Tolerances, the GD&T Interface has been dramatically improved to make it easier to add tolerances to your model. The tolerance callouts are also helpful when running sensitivity, as individual callouts are used to identify the source of variation, making your analysis much more granular.

2019 - March

Excel can be used for a lot of equation-based applications. Many companies rely on it for their tolerance analysis; doing 1D stacks and stack-up analysis. For basic cases, this works great and can be a fast and effective way to get answers quickly, but as soon as products, models, and requirements become more complex, Excel falls flat.

2019 - March

Model Variants have been added to the new version of 3DCS. This much-requested feature allows users to designate different model builds within the same model. This reduces issues with version control, as well as removing the need for multiple cloned versions of the same model in order to simulate different processes, parts or tolerance schemes. Now, within the same model, users can define different assembly methods, tolerances or GD&T, and measurements for each variant, swapping between them with the push of a button.

2019 - April

Equation Measure - Learn how to make custom measurements in 3DCS based on equations, if/then logic, conditional logic, and other custom inputs and outputs.

Measure Equation uses feature locations, vectors, directions, or even other measurements as inputs and outputs a value based on various math operations. It also allows conditional operators in the form of "If... then... else..." statements. If there is an output that can't be determined with the standard measurement types, chances are the Measure Equation DLL will be able to determine the output.

2019 - May

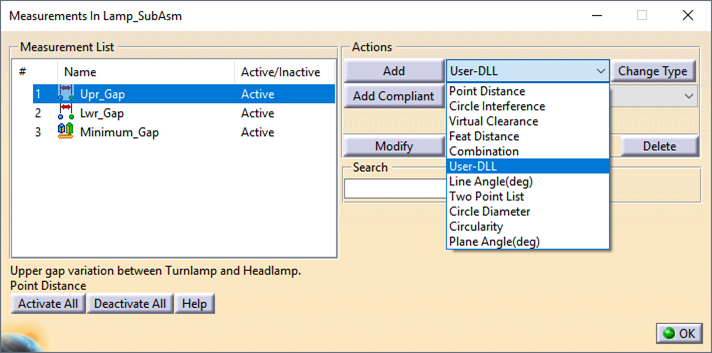

Measurements are what give you your outputs in 3DCS. These measurements can be used to simulate the real methods of inspection; how a FARO arm will measure the parts, or a check gage or fixture, or can be simple point-to-point measurements to give you the final value.

2019 - June

Featuring Guest Presenter Ryan Gelotte, CTO at Action Engineering

A QIF Case Study – Maintaining the Digital Thread from OEM to Supplier

Passing 3D model data without a drawing from an Original Equipment Manufacturer (OEM) to a supplier generally creates interoperability chaos - how do you streamline this process?

2019 - July

This webinar showcases the new version of 3DCS now fully integrated into SOLIDWORKS.

See how this new integration can help streamline your modeling process and deliver unparalleled results to reduce defects, scrap, and rework in manufacturing.

Some key highlights:

2019 - September

The August 2019 Webinar will demonstrate how to use the Batch Processor for a number of different types of analysis:

The Batch Processor allows running the Statistical Analysis outside of 3DCS environment. It is advantageous to use Batch Processor for models with a large number of parts and/or a large number of calculations.

2019 - November

XForm DLL - a built-in tool for 3DCS. The purpose of this module is to allow parts or features to be translated, rotated, or transformed by a specific amount. This amount can be specified as a constant value or a calculated value from a measurement.

2019 - December

This webinar will discuss the steps to modeling in 3DCS, and Vince Radziecki, Senior Advanced Manufacturing Engineer at Bordrin New Energy Vehicle Company, will demonstrate examples and a Case Study demonstrating the early steps that make modeling not only easier, but more effective. In addition, he will be showcasing the modeling process itself with an example model he completed.

2020 - January

Learn how to create, organize, and filter your FTA in CATIA, then create 2D Drawings from your CAD with presenters Gary Carne, Dassault Systemes, and Gary Bell, DCS Sr. Variation Analyst. Then pass your FTA to 3DCS for validation and optimization before pushing it back into your CAD.

2020 - February

Learn how to use Live Rendering in 3DEXPERIENCE along with 3DCS Spec Studies to display tolerance scenarios on your product. As part of the webinar, Daniel will show how to utilize the 3DEXPERIENCE Platform's Live Rendering to visualize gap and flush conditions in order to determine acceptable tolerance objectives. This will be compared to Spec Studies created from Tolerance Stack Up outputs, called Variation Studies, to see whether the objectives chosen by the design team can be met by the manufacturing engineer's specifications.

2020 - March

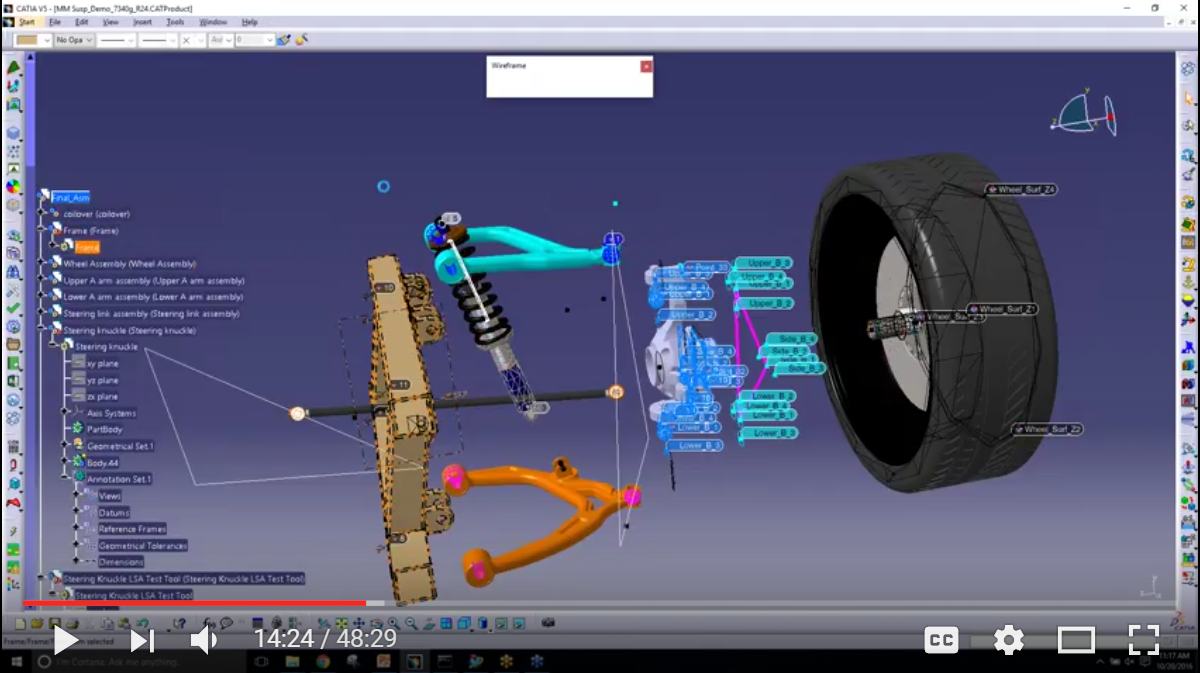

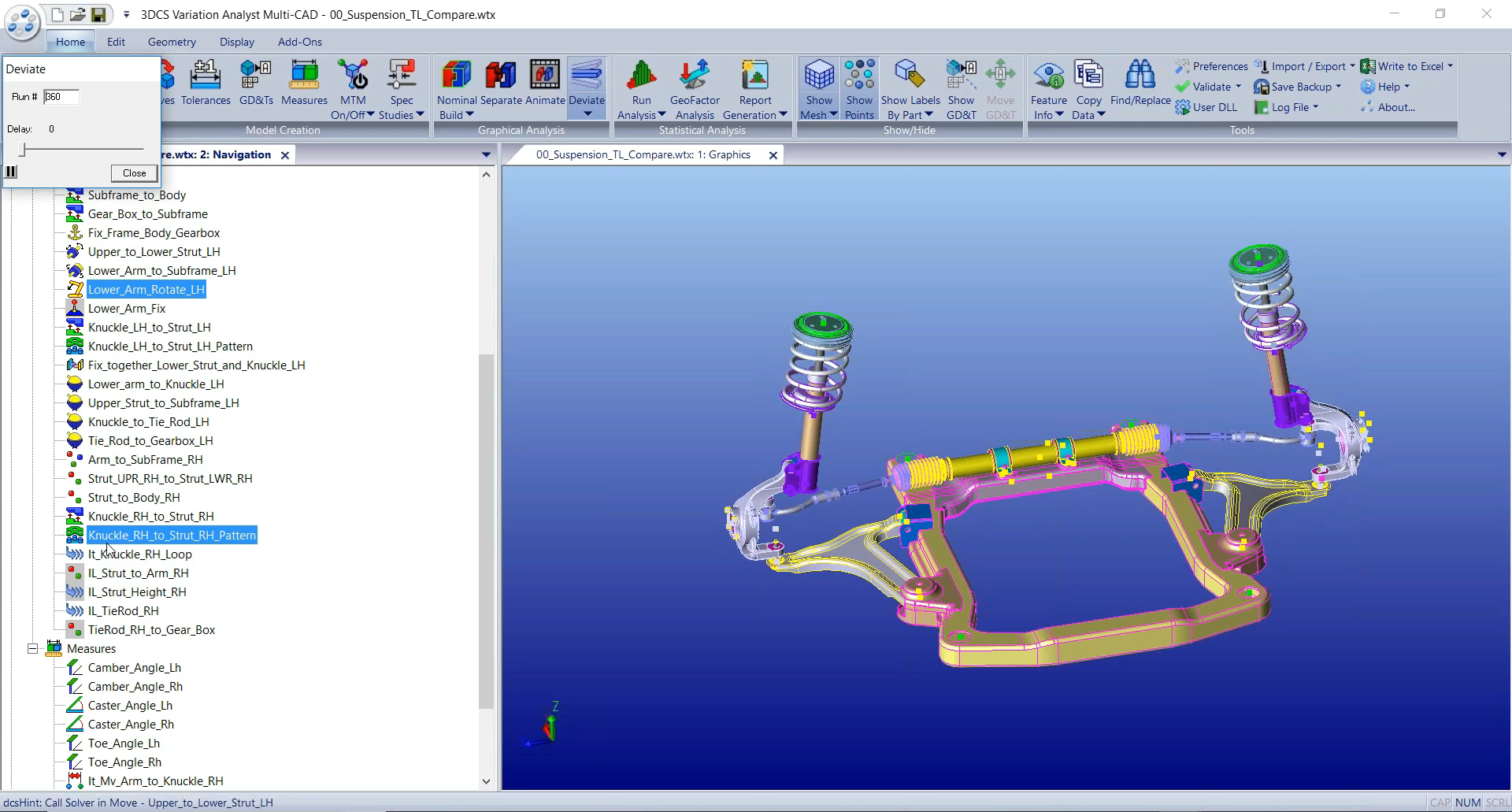

This special event will walk through a completed model, showing how it was constructed, including the inputs and outputs. The outputs include comparing the rigid kinematic model to the compliant kinematic model, an analysis of the bump steer impact from variation, and wheel alignment changes (camber, caster, toe).

2020 - April

Learn about the newly available features in 3DCS version 7.7 including:

2020 - March

QDM 3D Analyst has been expanded on in the new Version 8.1 Release. This release compiles all of the updates, enhancements, and new features added over the last 12 months to make it easy to utilize in your quality reporting and SPC studies.

2020 - April

The New Version of 3DCS - 7.7 The new version of 3DCS has a long list of fixes and updates, with some key new features that will help improve your modeling experience.

Part 2 Covers:

2020 - May

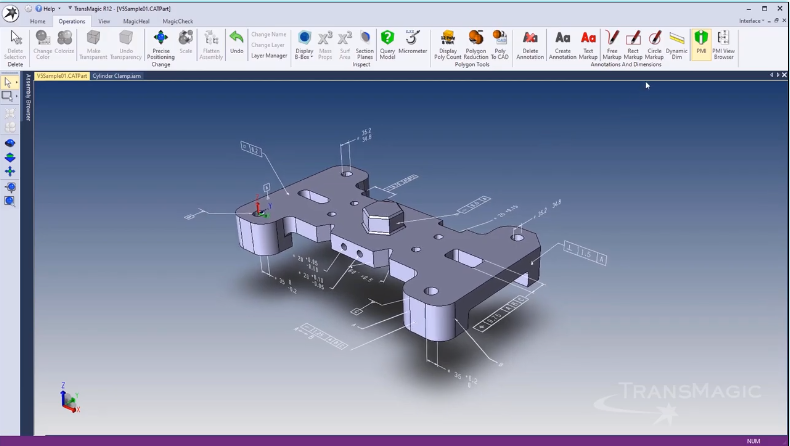

TransMagic CAD translation software automates complex and time-consuming processes so users can get more work done.

With a library of tools to help you work between CAD systems, TransMagic helps translate, repair, and compare CAD models.

2020 - May

Reduce lead and launch time by eliminating or minimizing manual join & clamp sequence studies by determining the optimal join and clamp sequence from a candidate set.

Using sequence optimization improves the overall process by optimizing the travel path as part of the sequence set. This helps eliminate the problem of optimized sequences that ignore travel path and increase the cycle time to unacceptable levels.

2020 - June

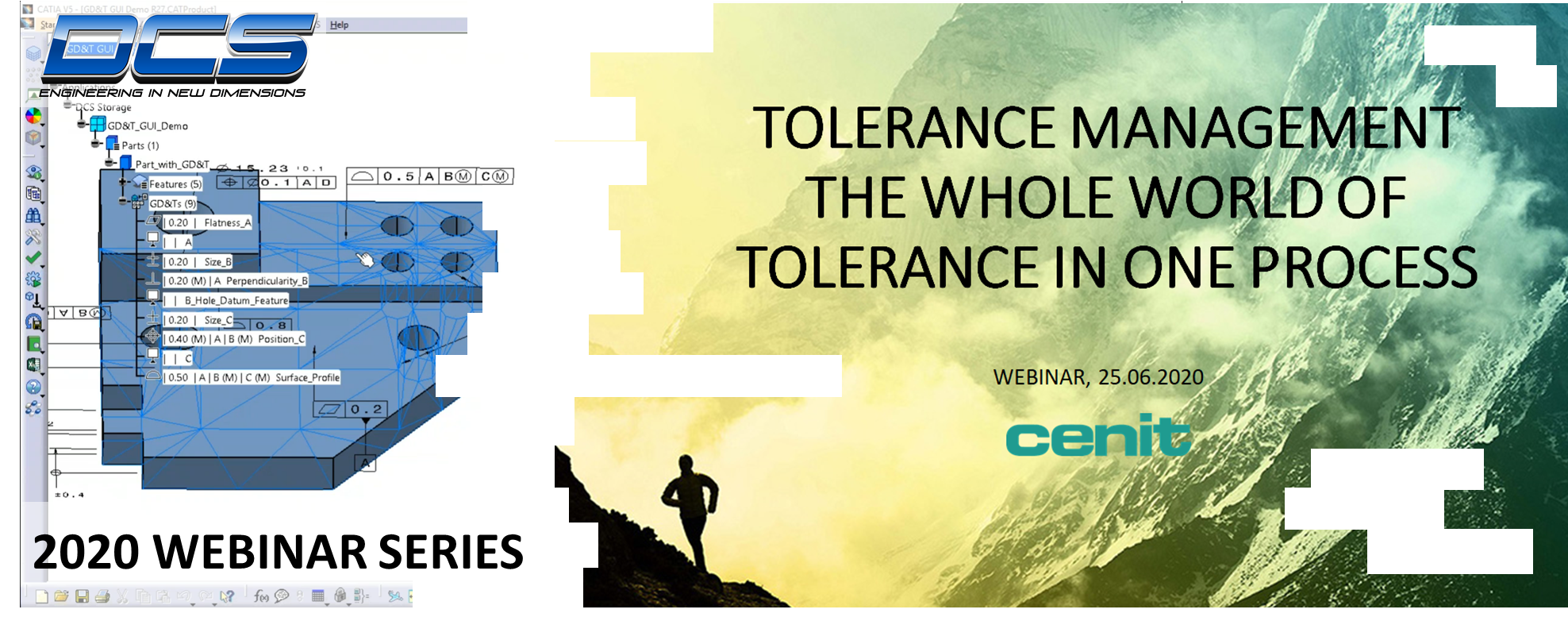

Join Uli Decker from DCS partner CENIT and Gary Bell, senior dimensional engineer at DCS, as they demonstrate the purpose and value of dimensional management through easy-to-understand anecdotes and examples.

Key Takeaways:

1. What is dimensional management?

2. What are the contributors to dimensional management?

3. What is the value of dimensional management at the organization?

4. How does 3DCS support dimensional management?

2020 - August

Effective communication with suppliers is difficult. Sending information via email can be disjointed, lead to missed messages and files, and is open to data insecurity.

A connected method of communication - providing instructions to suppliers for measurement and standards, and the supplier a means of reporting measurements and providing documents (Ppap, FAIR) back to the OEM - is essential to an effective supplier quality assurance program.

This webinar will demonstrate three methods of communicating with suppliers - sharing documents, correlating measurements, and negotiating tolerances.

Supplier Quality Data Management

Supplier Quality Document Management

Supplier Quality – Tolerance Negotiations

3DCS can assess gear backlash and mounting misalignments, perform angular backlash analysis, and create flank test displays and contact patterns. Here are some of the measurements it supports:

-- Backlash and system backlash.

-- Line of action contact.

-- Center mounting distance.

-- Mounting angles.

-- Contact pressure angles.

-- Flank contact area.

-- Radial tooth interface.

-- Radial tooth gap.

2020 - October

The NEW 3DCS Datum Optimizer is a tool using a genetic algorithm to determine the optimal datum features from a candidate set with the goal of minimizing the rigid part variation or compliant part deformation.

Using Datum Optimizer during the design stage and prior to production, users can eliminate or minimize mechanism rework and tuning by selecting the best datum features while increasing confidence in passing Gage Repeatability and Reproducibility (Gage R&R) studies.

2020 - November

With new optimizers, measures, and enhancements, this new release provides helpful tools for your modeling.

Version 7.7.1.0 of 3DCS Variation Analyst is now available through DCS' FileShare.

With the new release, 3DCS gains some helpful enhancements to preferences, as well as two new measurements. This webinar covers: 1. Dimension Distance Measure 2. Volume Measurement 3. Misc Enhancements 4. What’s New Documentation

2022 - February

In the webinar, learn about the new features and updates added in the 7.8.1 update to 3DCS software. These include changes to or new inclusions of:

December 2020

DCS is proud to present guest speaker Hanchen Zheng, Daimler. Zheng will be discussing the process, inputs, and results from his validation study on 3DCS FEA Compliant Modeler on BIW parts.

This paper proposes an approach to implement tolerance simulation for a compliant assembly, which includes manufacturing processes such as clinching, bolting, and hemming by applying a tolerance simulation tool.

2021 January

Improper selection of datum features during manufacturing and assembly may cause severe quality problems. Improper datum features risk turning all the quality parts, accurate dimensioning and tolerancing, and first-class operations into a defective assembly.

Part of the IMTS SPARK 2021 Webinar Series

2021 - August

The 7.8 series will showcase four new features:

2021 - March

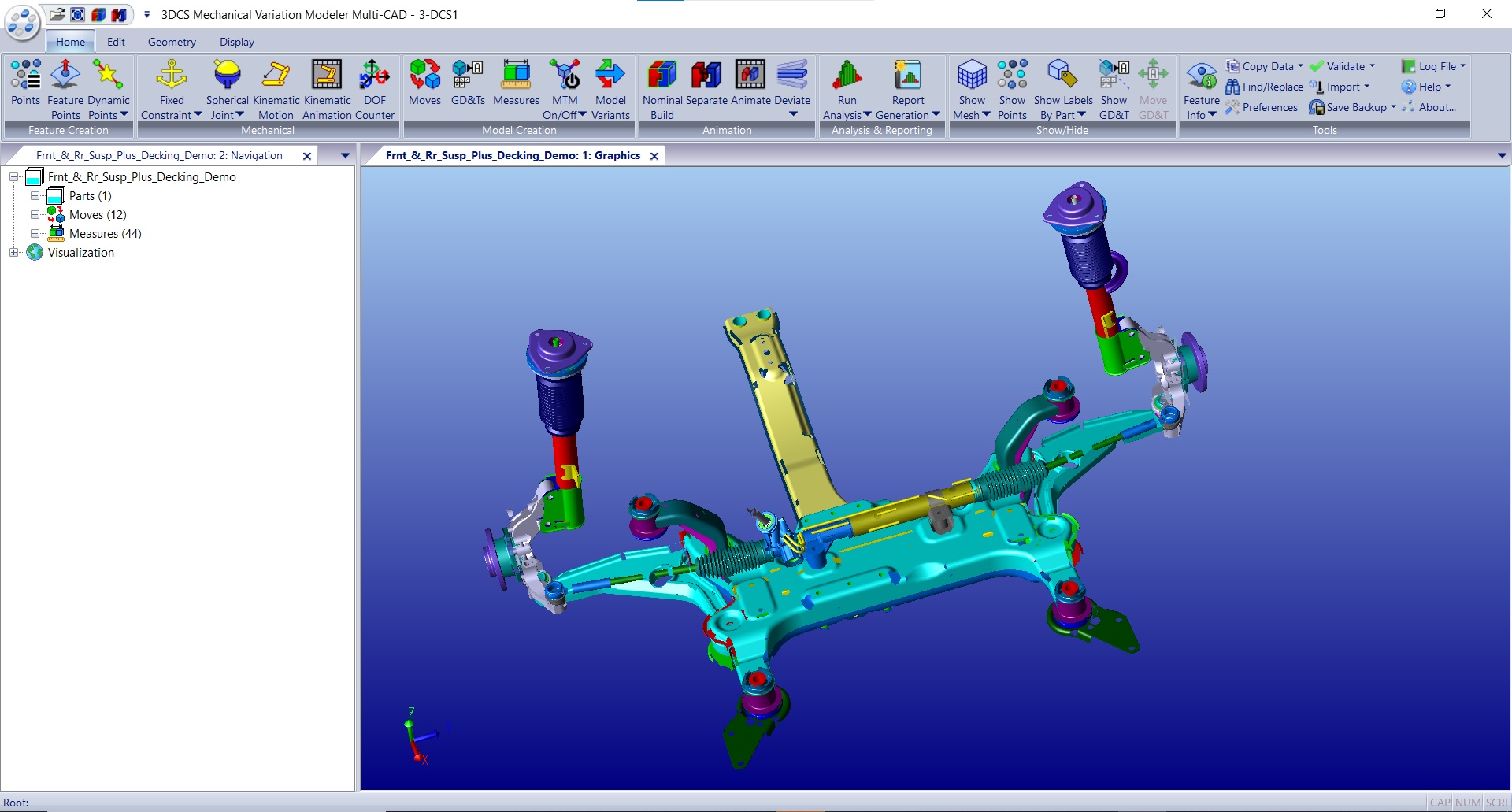

3DCS Mechanical Variation Modeler is built on the 3DCS platform incorporating 3DCS Mechanical Modeler into its base functionality to model complicated linkages and mechanical assemblies with easy-to-apply Constraints, Joints, and a DCS Feature Move.

2021 - September

The 7.8 series will showcase four new features:

2021 - November

Put down the Excel Spreadsheet, set aside the clipboard, ignore that huge stack of papers, and finally take control of your quality.

QDM Cloud delivers fast, reliable, and secure QMS and SPC reporting wherever you are in the world. With QDM Cloud, you can get set up and running in 4 hours for less than $1000.

QIF compatible and CAD connected to supercharge your Digital Transformation and MBD initiatives.

2022 - January

In the webinar, a 3DCS variation analysis software model will be used to validate the design and tolerancing of an individual gear. Standard tests and gear specification measurements are calculated using Monte Carlo simulation and predicted results are displayed including predicted deviation from nominal values and predicted range of values.